Precision & Versatility for Standing Seam Profiles

The EPM-25 Profiling Machine is designed to efficiently produce double standing seam profiles (25 mm) from blanks or cut lengths in two passes. Ideal for entry-level users or as a reliable backup machine for on-site work, it offers precision, flexibility, and ease of use.

Possible versions

Profile dimensions

Key Features & Benefits:

- Versatile Production– Produces conical, oblique, and standing seam panels with a centre-to-centre distance starting from 50 mm.

- Compact & Efficient– Handles panel lengths as short as 300 mm at a production rate of 11 meters per minute.

- Precision Engineering– The torsion-proof steel frame supports a 7-level profiling unit, ensuring accurate and stable shaping.

- Durable & Wear-Resistant– High-quality surface-treated steel rollers provide superior corrosion and wear protection.

- Material Adaptability– Resilient mounts on the upper profile rollers adjust automatically to material thickness, ensuring impression-free, low-wear production.

- Portable & Easy Setup– Lightweight with plug-in carrying handles for quick transport and setup, making it perfect for on-site applications.

Ideal for Short, Conical & Pointed Panels

Designed for precision and efficiency, the EPM-25 is the perfect solution for professionals seeking a high-performance, mobile profiling machine for workshop and construction site use.

VIDEO

DOWNLOADS

TECHNICAL INFORMATION

| Supply voltage | 230 V / 50 Hz / 1 Ph. |

| Drive power | 1.1 kW |

| Working speed | 8,5 m/min |

| Forming stages | 7 stations |

| Shortest panel length | 250 mm |

| Infeed height | 870 mm |

| Processable materials | Titanium zinc up to 0.8 mm Copper up to 0.8 mm Aluminium up to 0.8 mm Sheet steel (galvanized and coated) up to 0.7 mm Stainless steel up to 0.5 mm |

| Dimensions (L x W x H) | 950 / 1,250 mm x 600 mm x 1,070 mm |

| Weight | 180 kg |

a) Axial Dimension

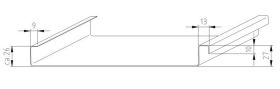

The corresponding strip widths result in the following profile dimension fort he profile height 25

b) Covering Width

During installation, the resulting covering widths must be considered

c) Variants

The following profiles can be manufactured on the machine

SYSTEM DESCRIPTION

Schlebach machines are characterized by the highest precision and user-friendliness. Get to know the folding techniques and backgrounds of the processing of metal.

LAYING

Learn more about laying finished sheets with a Schlebach machine.

ACCESSORIES

GUIDEBOY

Precision Material Guide for Single-Sided Profiling

The Guideboy is an additional material guide designed to ensure accurate single-sided profile shaping of panels. Compatible with all Schlebach profile shaping machines, it can be easily installed on the infeed guides with minimal effort.

- Prevents Material Shift– Keeps sheet metal aligned and prevents it from shifting towards the machine’s center during single-sided profiling operations.

- Adjustable Control– The lateral force across the profiling direction can be fine-tuned by adjusting the directional angle and contact pressure for optimal shaping results.

- Surface Protection– High-quality pressure rollers with a special rubber coating prevent surface damage, ensuring a smooth, mark-free finish.

The Guideboy is a simple yet effective solution for enhancing profiling precision while maintaining material integrity.

- Technical Information

-

TECHNICAL INFORMATION

Supply voltage 230 V / 50 Hz / 1 Ph. Drive power 1.1 kW Working speed 8,5 m/min Forming stages 7 stations Shortest panel length 250 mm Infeed height 870 mm Processable materials Titanium zinc up to 0.8 mm

Copper up to 0.8 mm

Aluminium up to 0.8 mm

Sheet steel (galvanized and coated) up to 0.7 mm

Stainless steel up to 0.5 mmDimensions (L x W x H) 950 / 1,250 mm x 600 mm x 1,070 mm Weight 180 kg - Profile Infromation

-

DIMENSIONS STANDING SEAM 25

a) Axial Dimension

The corresponding strip widths result in the following profile dimension fort he profile height 25

b) Covering Width

During installation, the resulting covering widths must be considered

c) Variants

The following profiles can be manufactured on the machine

SYSTEM DESCRIPTION

Schlebach machines are characterized by the highest precision and user-friendliness. Get to know the folding techniques and backgrounds of the processing of metal.

LAYING

Learn more about laying finished sheets with a Schlebach machine.

- Accessories

-

ACCESSORIES

GUIDEBOY

Precision Material Guide for Single-Sided Profiling

The Guideboy is an additional material guide designed to ensure accurate single-sided profile shaping of panels. Compatible with all Schlebach profile shaping machines, it can be easily installed on the infeed guides with minimal effort.

- Prevents Material Shift– Keeps sheet metal aligned and prevents it from shifting towards the machine’s center during single-sided profiling operations.

- Adjustable Control– The lateral force across the profiling direction can be fine-tuned by adjusting the directional angle and contact pressure for optimal shaping results.

- Surface Protection– High-quality pressure rollers with a special rubber coating prevent surface damage, ensuring a smooth, mark-free finish.

The Guideboy is a simple yet effective solution for enhancing profiling precision while maintaining material integrity.

MORE PRODUCTS AND SOLUTIONS

Profiling machine MINI-LIGHT

Our profiling machine MINI-LIGHT – For the production of double lock standing seam profile 25 from blanks or sheet material in one pass

Profiling machine MINI-PROF

Our profiling machine MINI-PROF – Suitable for beginners or as a second machine for the production of double lock standing seam profile 25

Profiling machine MINI-PROF PLUS

Our profiling machine MINI-PROF PLUS – Compact machine for the production of double lock standing seam profile 25 from blanks, from sheet material or directly from coil

Profiling machine MINI-RSM

Our MINI-RSM profiling machine – With digital length measurement in mm graduation, a driven strip infeed and a motor-driven roller shear for cross cutting before profiling.