Compact & Versatile Profiling Machine

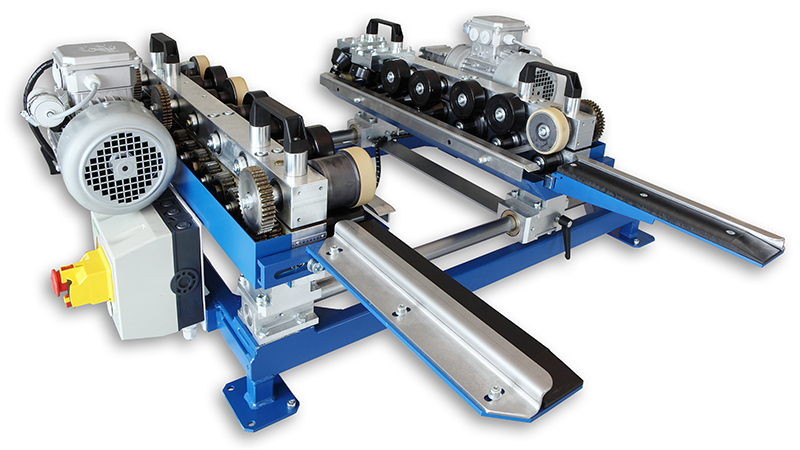

The MINI-LIGHT profiling machine is designed for efficient double standing seam profile 25 production from blanks or cut lengths in a single pass. Its lightweight, compact, and easily disassembled design makes it ideal for hard-to-reach construction sites and small workshop operations.

Opened machine

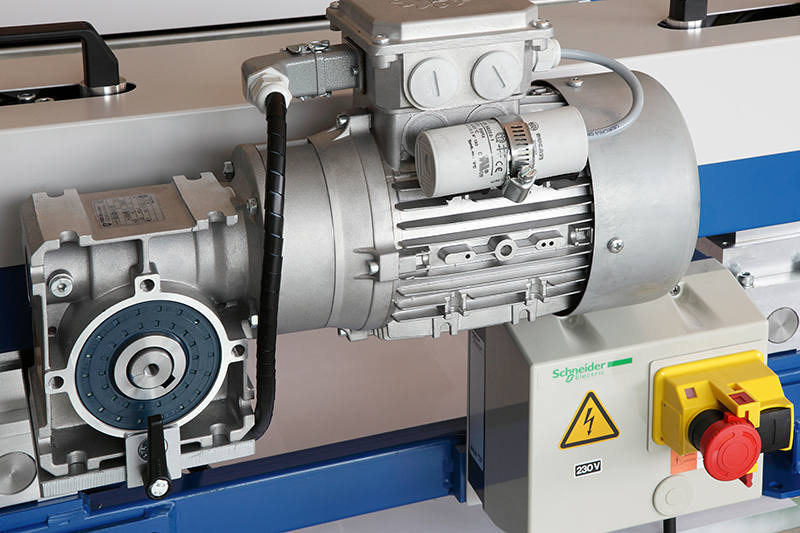

Electrical drive

Profile dimensions

Key Features:

- Quick Assembly & Portability– Composed of four lightweight components, the MINI-LIGHT can be assembled and ready for operation in no time. Equipped with built-in carrying handles, it allows for easy transport and setup in challenging locations.

- Flexible Infeed Width– Continuously adjustable from 250 mm to 730 mm, accommodating a wide range of applications. The profile panel width ranges from 180 mm to 660 mm, considering a seam loss of 70 mm.

- Versatile Profiling Capabilities– A single-sided run can produce conical, oblique panels, or infill strips with a minimum center-to-center distance of 50 mm. Shortest panel length: 500 mm.

- High-Speed Production– The MINI-LIGHT operates at 11 meters per minute, ensuring efficient panel production.

- Precision Engineering– Built with torsion-proof steel frames and high-quality special steel profile rollers with a corrosion-resistant surface treatment, ensuring durability and low-wear operation.

- User-Friendly Operation– Simply adjust the infeed guides, turn on the profile shaping drive, and manually feed the panels for a smooth and seamless production process.

Perfect for Global Roofing Needs

Whether you’re working on remote construction sites or small-scale projects, the MINI-LIGHT delivers professional-grade profiling performance in an ultra-portable and easy-to-use design.

VIDEO

DOWNLOADS

TECHNICAL INFORMATION

| Supply voltage | 230 V / 50 Hz / 1 Ph. |

| Drive power | 2 x 0.55 kW |

| Operating speed | 8 m/min |

| Forming stages | 7 stations |

| Shortest panel length | 500 mm |

| Infeed width | 250 – 730 mm |

| Axial dimension | approx. 180 – 660 mm (depending on the material) |

| Infeed height | 286 mm |

| Processable materials | Titanium zinc up to 0.8 mm Copper up to 0.8 mm Aluminium up to 0.8 mm Sheet steel (galvanized and coated) up to 0.7 mm Stainless steel up to 0.5 mm |

| Dimensions (L x W x H) | 1,200 mm x 1,290 mm x 460 mm |

| Weight | 155 kg |

ASSEMBLY

The profile shaping machine can be diassembled into 4 components without the need of any tools:

- Tie-bar adjustable side

- Tie-bar fixed side

- Frame

- Centre support

1 – Diassembled machine:

2 – Mounting the tie-bar on the adjustable side and the centre support on the frame:

3 – Mounting the tie-bar on the fixed side:

PROFILE INFORMATION

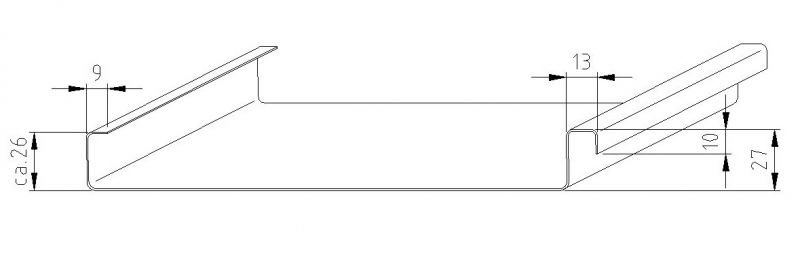

DIMENSIONS STANDING SEAM 25

a) Axial Dimension

The corresponding strip widths result in the following profile dimension for the profile height 25

b) Covering Width

During installation, the resulting covering widths must be considered

c) Variants

The following profiles can be manufactured on the machine

SYSTEM DESCRIPTION

Schlebach machines are characterized by the highest precision and user-friendliness. Get to know the folding techniques and backgrounds of the processing of metal.

LAYING

Learn more about laying finished sheets with a Schlebach machine.

- Technical Information

-

TECHNICAL INFORMATION

Supply voltage 230 V / 50 Hz / 1 Ph. Drive power 2 x 0.55 kW Operating speed 8 m/min Forming stages 7 stations Shortest panel length 500 mm Infeed width 250 – 730 mm Axial dimension approx. 180 – 660 mm (depending on the material) Infeed height 286 mm Processable materials Titanium zinc up to 0.8 mm

Copper up to 0.8 mm

Aluminium up to 0.8 mm

Sheet steel (galvanized and coated) up to 0.7 mm

Stainless steel up to 0.5 mmDimensions (L x W x H) 1,200 mm x 1,290 mm x 460 mm Weight 155 kg - Assembly

-

ASSEMBLY

The profile shaping machine can be diassembled into 4 components without the need of any tools:

- Tie-bar adjustable side

- Tie-bar fixed side

- Frame

- Centre support

1 – Diassembled machine:

2 – Mounting the tie-bar on the adjustable side and the centre support on the frame:

3 – Mounting the tie-bar on the fixed side:

- Profile Information

-

PROFILE INFORMATION

DIMENSIONS STANDING SEAM 25

a) Axial Dimension

The corresponding strip widths result in the following profile dimension for the profile height 25

b) Covering Width

During installation, the resulting covering widths must be considered

c) Variants

The following profiles can be manufactured on the machine

SYSTEM DESCRIPTION

Schlebach machines are characterized by the highest precision and user-friendliness. Get to know the folding techniques and backgrounds of the processing of metal.

LAYING

Learn more about laying finished sheets with a Schlebach machine.

MORE PRODUCTS AND SOLUTIONS

Profiling machine EPM-25

Our EPM-25 profiling machine – For double lock standing seam profile 25 and one-sided profiling in two operations

Profiling machine MINI-PROF

Our profiling machine MINI-PROF – Suitable for beginners or as a second machine for the production of double lock standing seam profile 25

Profiling machine MINI-PROF PLUS

Our profiling machine MINI-PROF PLUS – Compact machine for the production of double lock standing seam profile 25 from blanks, from sheet material or directly from coil

Profiling machine MINI-RSM

Our MINI-RSM profiling machine – With digital length measurement in mm graduation, a driven strip infeed and a motor-driven roller shear for cross cutting before profiling.