Advanced Profiling Machine for Seamless Efficiency

The MINI-PROF PLUS is a high-performance profiling machine designed for precise double standing seam profile 25 production from blanks, cut lengths, or directly from a coil. This upgraded version of the MINI-PROF integrates automated features for enhanced efficiency, accuracy, and ease of operation.

Profilabmessungen

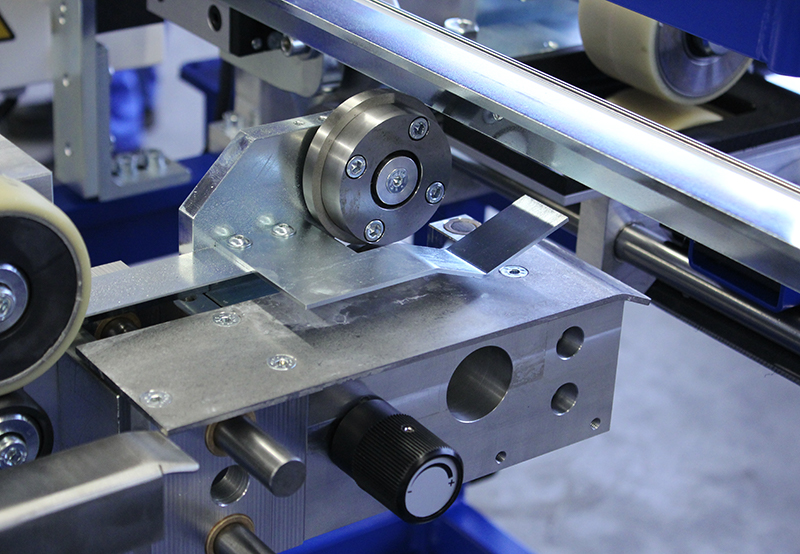

Manual cross-cutting roller shear RS

Longitudinal cutter LS (optional)

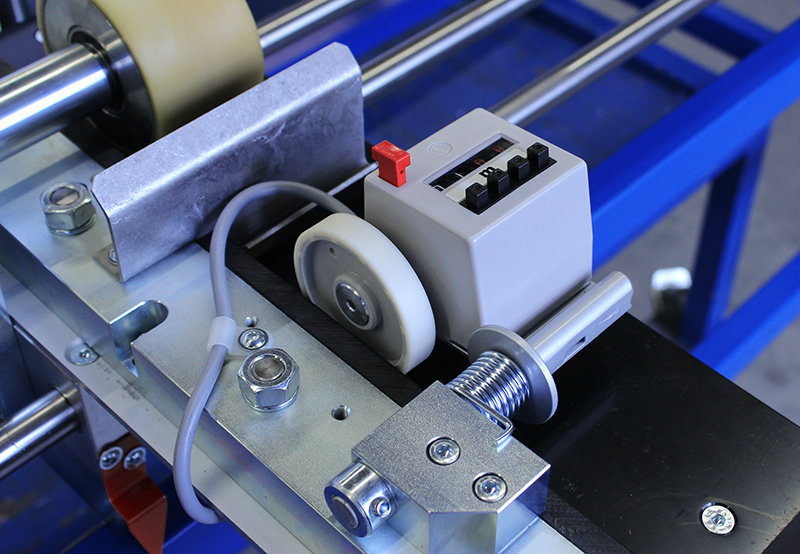

Electromechanical length measuring device

Enhanced Features & Functionality

- Integrated Infeed System– The MINI-PROF PLUS includes an electromechanical length measuring device with a centimeter scale, a driven belt feeder, and a hand-operated roller shear for manual cross-cuts.

- Versatile Coil Processing– Comes equipped with a decoiler (AC type) and roller shear (LS) for longitudinal slitting. On request, the machine can be supplied without AC and LS.

- Adjustable Infeed Width– Ranging from 240 mm to 850 mm, allowing for a wide variety of applications. The profile panel width varies from 170 mm to 780 mm, considering a seam loss of 70 mm.

High-Precision Manual Roller Shear

- Equipped with hardened roller blades, which can be resharpened or replaced

if necessary. - Mounted on a maintenance-free linear roller guide to ensure a clean, burr-free cut.

Efficient Production Process

- 11 meters per minute production speed.

- Single-sided runs allow for conical and oblique panel production, with a minimum center-to-center distance of 80 mm.

- Minimum panel length: 500 mm.

Automated Length Control for Coil Processing

- The required cutting length is entered via push buttons on the electromechanical length measuring unit.

- The material is automatically fed using driven feed rollers.

- Upon reaching the programmed length, an electrical impulse stops the profiling process, ensuring accuracy.

- Length tolerance: 1-2 cm.

- Once the manual shear cut is completed, the system must be reset before continuing.

Longitudinal Slitting with LS Unit

- The LS cutting position is manually set and marked on the sheet.

- Scrap strips are guided downward for easy disposal.

Robust & User-Friendly Design

- Precision Engineering – Built on a torsion-proof steel frame, with lateral infeed guides on ball bearings for smooth, precise material guidance.

- Durable & Low-Wear Components – High-quality special steel profile rollers with a corrosion-resistant surface treatment ensure long-lasting performance.

- Ergonomic & Portable – Mounted on 4 castors, with 2 lockable wheels for stability.

- Adjustable working height (670 mm – 870 mm) with extendable footrests and lockable castors.

- Can be moved by crane using the supplied eye-bolts for easy transport.

The Ultimate Solution for Onsite & Workshop Profiling

The MINI-PROF PLUS offers seamless coil processing, high precision, and mobility, making it the perfect choice for construction sites and workshop operations.

VIDEO

DOWNLOADS

TECHNICAL INFORMATION

| Supply voltage | 230 V / 50 Hz / 1 Ph. 115 V / 50 Hz / 1 Ph. 115 V / 60 Hz / 1 Ph. |

| Drive power | 1.1 kW |

| Operating speed | 8.5 m/min |

| Forming stages | 7 stations |

| Shortest panel length | 500 mm |

| Infeed width | 240 – 850 mm |

| Axial dimension | approx. 170 – 780 mm (depending on the material) |

| Infeed height | 670 – 870 mm (continuously variable) |

| Processable materials | Titanium zinc up to 0.8 mm Copper up to 0.8 mm Aluminium up to 0.8 mm Sheet steel (galvanized and coated) up to 0.7 mm Stainless steel up to 0.5 mm |

| Dimensions (L x W x H) | 1.600 mm x 1.370 mm x 850 – 1050 mm |

| Weight | 315 kg |

ACCESSORIES

GUIDEBOY

Precision Material Guide for Single-Sided Profiling

The Guideboy is an additional material guide designed to ensure accurate single-sided profile shaping of panels. Compatible with all Schlebach profile shaping machines, it can be easily installed on the infeed guides with minimal effort.

- Prevents Material Shift– Keeps sheet metal aligned and prevents it from shifting towards the machine’s center during single-sided profiling operations.

- Adjustable Control– The lateral force across the profiling direction can be fine-tuned by adjusting the directional angle and contact pressure for optimal shaping results.

- Surface Protection– High-quality pressure rollers with a special rubber coating prevent surface damage, ensuring a smooth, mark-free finish.

The Guideboy is a simple yet effective solution for enhancing profiling precision while maintaining material integrity.

RIBBING ATTACHMENT 25 MM

The Ribbing Attachment Assembly is designed to form longitudinal ribs with a 25 mm width and an approximate 1.1 mm depth on the visible surface of profiled panels.

Features & Benefits

- Precision Ribbing– The assembly includes a guide unit, upper and lower ribbing rollers, and brackets to ensure consistent rib formation.

- Surface Protection– High-quality ribbing rollers mounted on ball bearings minimize friction, preventing surface damage during profiling.

- Adjustable Spacing– The ribbing attachments are continuously adjustable along the profile shaping direction, allowing for custom rib spacing as per design requirements.

Note: Rib profiling is not possible on conical shapes.

DECOILER TRANS-ASPO

TRANS-ASPO Uncoiler – Fast & Efficient Coil Handling

The TRANS-ASPO uncoiler is designed for the quick and effortless handling of 1-ton coils. Thanks to its flying bearing system and manual height adjustment, coils can be easily positioned on the tensioning mandrel and secured without the need for additional lifting equipment.

Key Features:

- Effortless Coil Handling– Manual height adjustment allows easy coil placement.

- No Lifting Equipment Required– Coils can be tensioned manually, simplifying the process.

Highly Mobile – Equipped with four travel rollers, including two with fixing brakes, ensuring smooth positioning in front of the working machine.

PROFILE INFORMATION

DIMENSIONS STANDING SEAM 25

a) Axial Dimension

The corresponding strip widths result in the following profile dimension for the profile height 25

b) Covering Width

During installation, the resulting covering widths must be considered

c) Variants

The following profiles can be manufactured on the machine

SYSTEM DESCRIPTION

Schlebach machines are characterized by the highest precision and user-friendliness. Get to know the folding techniques and backgrounds of the processing of metal.

LAYING

Learn more about laying finished sheets with a Schlebach machine.

- Technical Information

-

TECHNICAL INFORMATION

Supply voltage 230 V / 50 Hz / 1 Ph.

115 V / 50 Hz / 1 Ph.

115 V / 60 Hz / 1 Ph.Drive power 1.1 kW Operating speed 8.5 m/min Forming stages 7 stations Shortest panel length 500 mm Infeed width 240 – 850 mm Axial dimension approx. 170 – 780 mm (depending on the material) Infeed height 670 – 870 mm (continuously variable) Processable materials Titanium zinc up to 0.8 mm

Copper up to 0.8 mm

Aluminium up to 0.8 mm

Sheet steel (galvanized and coated) up to 0.7 mm

Stainless steel up to 0.5 mmDimensions (L x W x H) 1.600 mm x 1.370 mm x 850 – 1050 mm Weight 315 kg - Accessories

-

ACCESSORIES

GUIDEBOY

Precision Material Guide for Single-Sided Profiling

The Guideboy is an additional material guide designed to ensure accurate single-sided profile shaping of panels. Compatible with all Schlebach profile shaping machines, it can be easily installed on the infeed guides with minimal effort.

- Prevents Material Shift– Keeps sheet metal aligned and prevents it from shifting towards the machine’s center during single-sided profiling operations.

- Adjustable Control– The lateral force across the profiling direction can be fine-tuned by adjusting the directional angle and contact pressure for optimal shaping results.

- Surface Protection– High-quality pressure rollers with a special rubber coating prevent surface damage, ensuring a smooth, mark-free finish.

The Guideboy is a simple yet effective solution for enhancing profiling precision while maintaining material integrity.

RIBBING ATTACHMENT 25 MM

The Ribbing Attachment Assembly is designed to form longitudinal ribs with a 25 mm width and an approximate 1.1 mm depth on the visible surface of profiled panels.

Features & Benefits

- Precision Ribbing– The assembly includes a guide unit, upper and lower ribbing rollers, and brackets to ensure consistent rib formation.

- Surface Protection– High-quality ribbing rollers mounted on ball bearings minimize friction, preventing surface damage during profiling.

- Adjustable Spacing– The ribbing attachments are continuously adjustable along the profile shaping direction, allowing for custom rib spacing as per design requirements.

Note: Rib profiling is not possible on conical shapes.

DECOILER TRANS-ASPO

TRANS-ASPO Uncoiler – Fast & Efficient Coil Handling

The TRANS-ASPO uncoiler is designed for the quick and effortless handling of 1-ton coils. Thanks to its flying bearing system and manual height adjustment, coils can be easily positioned on the tensioning mandrel and secured without the need for additional lifting equipment.

Key Features:

- Effortless Coil Handling– Manual height adjustment allows easy coil placement.

- No Lifting Equipment Required– Coils can be tensioned manually, simplifying the process.

Highly Mobile – Equipped with four travel rollers, including two with fixing brakes, ensuring smooth positioning in front of the working machine.

- Profile Information

-

PROFILE INFORMATION

DIMENSIONS STANDING SEAM 25

a) Axial Dimension

The corresponding strip widths result in the following profile dimension for the profile height 25

b) Covering Width

During installation, the resulting covering widths must be considered

c) Variants

The following profiles can be manufactured on the machine

SYSTEM DESCRIPTION

Schlebach machines are characterized by the highest precision and user-friendliness. Get to know the folding techniques and backgrounds of the processing of metal.

LAYING

Learn more about laying finished sheets with a Schlebach machine.

MORE PRODUCTS AND SOLUTIONS

Profiling machine EPM-25

Our EPM-25 profiling machine – For double lock standing seam profile 25 and one-sided profiling in two operations

Profiling machine MINI-LIGHT

Our profiling machine MINI-LIGHT – For the production of double lock standing seam profile 25 from blanks or sheet material in one pass

Profiling machine MINI-PROF

Our profiling machine MINI-PROF PLUS – Compact machine for the production of double lock standing seam profile 25 from blanks, from sheet material or directly from coil

Profiling machine MINI-RSM

Our MINI-RSM profiling machine – With digital length measurement in mm graduation, a driven strip infeed and a motor-driven roller shear for cross cutting before profiling.