Electronic bending tools

EHRT’s electronic bending tools are known for their springback compensation and exceptional accuracy.

By means of a patented springback compensation, the workpiece can be bent to the desired angle with two strokes. After the first stroke, the integrated electronic angle measurement system measures the angle of the workpiece, and calculates how much the workpiece must be bent to achieve the desired bending angle. This means that no test workpieces are required, and the workpieces are bent at the desired angle from

the first part. Each type and batch of material has a different springback, which is individually compensated, ensuring that each part is identical.

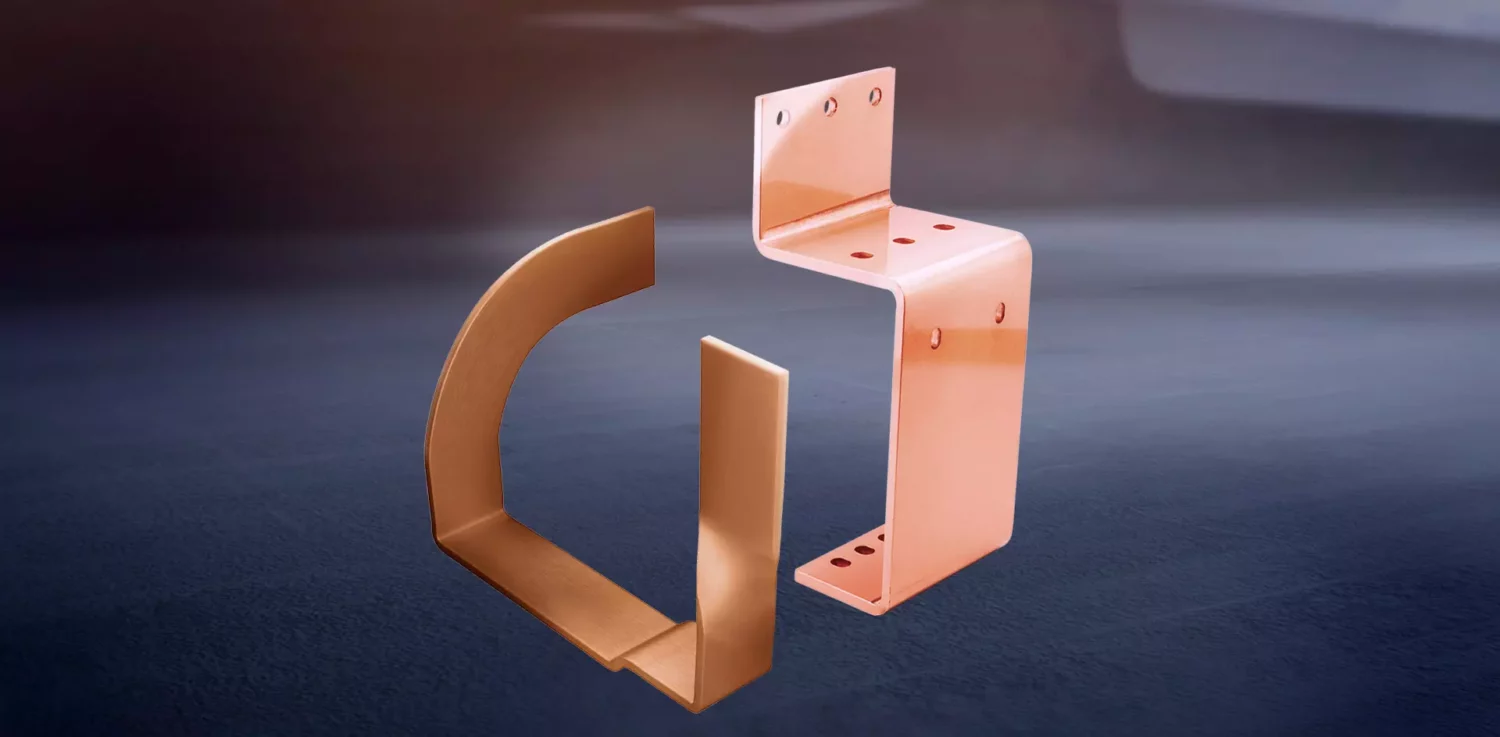

Mechanical bending tools

EHRT’s mechanical bending tools consist of bending former and bending prism.

When using a mechanical tool, the operator creates a stroke curve in advance to determine possible springback. This springback is then manually compensated by the operator. Mechanical tools are particularly suitable for contiguous bends. For high quantities, the processing speed with the mechanical tools is higher because the bends are made with one stroke.

Bending mandrel

When using a bending mandrel, the bending prism moves towards the bending mandrel and presses the bar material around the mandrel. Using a bending mandrel requires an existing tie rod. Narrower and closed bends are can be made with a bending mandrel.