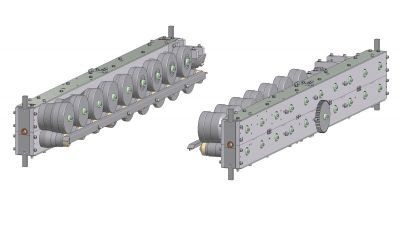

The QUADRO-KS profiling machine is another system that builds on the flexibility of the standard QUADRO machine. The QUADRO-KS variant enhances this flexibility by adding the conical profiling mode, which allows for the strip to be transported, cut at an angle, and profiled in a single operation, regardless of the profile shape. This feature makes the QUADRO-KS especially suitable for producing long, conical profile webs for applications like dome or tent roof shapes, as well as long conical fitting webs.

The machine benefits from the efficient interchangeable cassette system, enabling the production of a wide range of profiles. The changeover times are minimal, thanks to the ability to swivel or exchange cassettes quickly, making the QUADRO-KS both economical and efficient for varied production needs.

FEATURES – QUADRO SERIES

- Robust, versatile, and multifunctional design

- User-friendly PLC control with touch panel interface

- Stepless width adjustment from 300 – 800 mm (up to 1250 mm / XXL)

- Precision cutting with a low length tolerance of approx. 1-2 mm

- Adjustable feed rate: 14 m/min (optional 20 m/min)

- Wide selection of roof, façade, and special profiles tailored to customer needs

- Interchangeable cassette system for quick profile changes

- High-profile quality due to a large number of forming stations

- Single-sided passes possible for conical panel production

- Electrically powered roller shears for automatic cross-cutting

- Extensive accessory options for custom applications

- Minimum panel length: approx. 700 mm (varies by material and profile)

- Optional cutters for panel lengths over 100 mm

- Optional longitudinal cutter (LS) for producing fitting strips (see Quadro KS)

- Forklift pockets for safe and easy transport

QUADRO KS

- Most compact machine of the Quadro series

- Pivotable exchangeable cassettes with 10 forming stations

- Non-pivoting exchangeable cassettes with 12 forming stations

MORE INFORMATION

The QUADRO-KS variant, like the QUADRO profiling machine system, can produce sheet metal profiles for a wide range of applications efficiently and with high quality, while maintaining very short changeover times using just one basic machine. The machine utilizes the familiar exchangeable cassette system with 10 or 12 forming stations to produce various profile shapes.

The design of the QUADRO-KS allows the customer to configure the equipment and application range according to their needs. The machine can be retrofitted with additional cassettes or accessories at any time.

The QUADRO-KS is built on a sturdy base frame, designed to be mobile with four castors. Two of the castors can be fixed to prevent unintentional movement. Crane lugs and forklift pockets are included, ensuring safe transport on the construction site. The hinged covers, secured with a safety device, protect both the machine and the operator while facilitating adjustment work.

The infeed width can be adjusted continuously between 300 mm and 800 mm using a handwheel and spindle system. For tapered operation, the spindle adjustment can be disengaged, allowing the adjustment side to move freely in a special linear guide depending on the inclined position. The infeed area is equipped with robust ball-bearing infeed guides on both sides to ensure stable guidance of the strip material. These guides are separately adjustable to fine-tune the outer edges of the profile, ensuring smooth, precise feeding.

The QUADRO-KS is also equipped with a reinforced cut-to-length roller shear in the infeed area. The cutting head features hardened roller blades that can be reground or replaced easily. Mounted on a maintenance-free linear roller guide and driven by a toothed belt, the shear ensures a clean, burr-free cut. The shortest share length for this cutting process is approximately 700 mm. For shorter coulter lengths (around 100 mm), additional cutting devices can be mounted in the outfeed area. For non-ferrous metals, a QA60 can be used for the cut-off. A longitudinal cut-off device is available for conical profile webs, allowing the conical longitudinal cut before profiling.

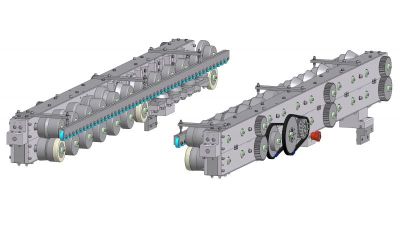

In the profiling area, the QUADRO-KS uses the proven interchangeable cassette system. Depending on the profile type, the system can accommodate cassettes with 10 or 12 profiling stations. The cassettes can be swapped or swiveled in a short amount of time, with changeover taking only a few minutes. The maximum changeover time is under 20 minutes, even when additional equipment like a forklift or table crane is needed. The profile rollers of the exchangeable cassettes are factory preset for material thicknesses between 0.5 and 0.7 mm, with special profiles available for thicknesses up to 1.0 mm.

The QUADRO-KS is equipped with a PLC for automatic processing of different lengths and quantities. The control system includes a menu-guided touch panel. For conical profiling, a separate submenu allows users to enter the required lengths for short and long widths and web length. The control system calculates the setting value for the inclined position of the cassette, which can be adjusted manually via the handwheel and spindle. Conical profiling can only be done in a single cycle. After each profile, the movable cassette must be returned to the start position manually before the next profile is processed.

In parallel profiling mode, when profiling from coil, the desired length and quantity are entered into the touch panel. The strip material is drawn into the machine via the transport rollers. Once the programmed length is reached, the drive stops, and the cutting process is automatically performed using the roller shears. The length tolerance is approximately 1 to 2 mm, and the next web starts automatically in automatic mode or is triggered manually in single-cycle mode. After the last profile is separated, the material feed can be stopped, and the belt can be manually retracted.

VIDEO

TECHNICAL INFORMATION

| Supply voltage | 230 V / 50 Hz / 1 Ph. 230 V / 60 Hz / 1 Ph. 400 V / 50 Hz / 3 Ph. 400 V / 60 Hz / 3 Ph. |

| Drive power | 2.2 kW |

| Operating speed | Default: 14 m/min Optional: 20 m/min |

| Infeed height | 900 mm |

| Infeed width | 300 – 800 mm |

| Shortest panel length | 700 mm (depending on material and profile) |

| Length tolerance | approx. 1 – 2 mm |

| Processable materials (profile dependent) |

Non-ferrous metals: Either 0.6 – 0.8 mm or 0.8 – 1.0 mm (has to be set before ordering) Non-ferrous metals: 1.0 – 1.2 mm (only with façade profiles) Steel (320 N/mm²): 0.55 – 0.70 mm Stainless steel: Max. 0.5 mm |

| Dimensions (L x W x H) | 3,830 mm x 2,045 mm x 1,275 mm |

| Weight | approx. 1,770 kg (with exchangeable cassettes) |

CONTROL VARIANTS

TOUCH PANEL CONTROL (PLC)

- Control panel with 5,7 Zoll touch screen (STN / colored)

- 4096 displayable colors

- Resolution 320 x 240

- Multilingual menu language

- User-friendly operator interface

- 25 program memory locations with each 40 program steps

- Manual operation as jogging mode

- Automatic operation in single-step and continuous operation

- Setting-up mode

- Feeder speed continuously adjustable with the control panel

TOUCH PANEL CONTROL (PLC) WITH GUIDE RAIL UNIT

- Control panel with 5,7 ” touch screen (STN / colored)

- 4096 displayable colors

- Resolution 320 x 240

- Multilingual menu language

- User-friendly operator interface

- 25 program memory locations with each 40 program steps

- Manual operation as jogging mode

- Automatic operation in single-step and continuous operation

- Setting-up mode

- Feeder speed continuously adjustable with the control panel

- Guide rail unit for comfortable operation of the control in the infeed or discharge area of the machine

TOUCH PANEL CONTROL (PLC) WITH GUIDE RAIL UNIT

- Control panel with 10,4 ” touch screen (STN / colored)

- 4096 displayable colors

- Resolution 640 x 480

- Multilingual menu language

- User-friendly operator interface

- 25 program memory locations with each 40 program steps

- Manual operation as jogging mode

- Automatic operation in single-step and continuous operation

- Setting-up mode

- Feeder speed continuously adjustable with the control panel

- Guide rail unit for comfortable operation of the control in the infeed or discharge area of the machine

PROFILE INFORMATION

CHANGING CASSETTES WITH 10 ROLLER STATIONS BOTH SIDES AND MAY BE SWIVELED

You can select 2 profiles

PROFILE SELECTION

| Double Standing Seam in height | 25, 32 and 38 mm |

| Double Standing Seam with Clip Relief in height | 25, 32 and 38 mm |

| Snap in height | 25 and 38 mm |

| Snap with Clip Relief in height | 25 and 38 mm |

| Nail Strip in height | 25 and 38 mm |

| U-profile | max. 36 mm |

PROFILE INFORMATION

Profile Standing Seam

Profiles Snap and Nailstrip

CHANGING CASSETTES WITH 10 ROLLER STATIONS ONE-SIDED AND CAN NOT BE SWIVELED

You can select 1 profile

PROFILE SELECTION

| Double Standing Seam50 mm | |

| Double Standing Seam 50 mm with Clip Relief | |

| Double Standing Seam 50 mm (2″) USA Version |

PROFILE INFORMATION

Profile Standing Seam

CHANGING CASSETTES WITH 12 ROLLER STATIONS ONE-SIDED AND CAN NOT BE SWIVELED

you can select 1 profile

PROFILE SELECTION

| Snap Lok 43,5 (1 3/4″) | |

| Sofit Panel | |

| Wall Panel | |

| Step Panel |

Profile Information

Profiles Snap and Nailstrip

Profile facade profile Prof88 and SOFFIT

Profile facade profile stepped tile panel

SPECIAL PROFILES ACCORDING TO CUSTOMER SPECIFICATIONS

Here some examples for special profiles:

PROFILE SELECTION

|

Hohlumschlag

|

|

Fensterbank 1

|

|

Fensterbank 2

|

|

Traufblech

|

|

Landhaus 1

|

|

Landhaus 2

|

|

Fassadenpaneel

|

|

Kühlfahrzeugeindeckung 1

|

|

Kühlfahrzeugeindeckung 2

|

|

Kühlfahrzeugeindeckung 3

|

|

Leistendach

|

|

Dachprofil

|

|

Containereindeckung 1

|

|

Containereindeckung 2

|

|

Kassettenpaneel

|

MORE INFORMATION

As with the QUADRO profiling machine system, the QUADRO-KS variant can also produce sheet metal profiles from a wide range of applications in a user-friendly manner and within the shortest possible changeover time in the highest quality with just one basic machine. The well-known exchangeable cassette system with 10 or 12 forming stations is used to produce the various profile shapes.

Due to the clever design, the customer is able to determine the equipment and thus the application area of the machine individually himself. Of course, the machine can also be retrofitted at any time with additional cassettes or extensive accessories.

The QUADRO-KS is built on a robust base frame and is designed to be mobile with 4 castors. Two casters can be fixed to prevent unintentional rolling away. Furthermore, the crane lugs included in the scope of delivery and the forklift pockets attached to the frame enable the machine to be transported safely on the construction site. This ensures flexible use of the machine both in operation and on the construction site. Hinged covers, which are secured by a safety device, protect the machine and the operator and facilitate the adjustment work.

The infeed width can be continuously adjusted between 300 and 800 mm via a handwheel with the proven spindle system. For tapered operation, the spindle adjustment is disengaged so that the adjustment side can move freely laterally in a special linear guide, depending on the inclined position. In the infeed area, the QUADRO-KS is equipped with robust ball-bearing infeed guides on the right and left for stable guidance of the strip material. These are designed to be separately adjustable for adjusting the outer edges of the profile. This allows the strip to be fed smoothly and without play.

The additionally reinforced cut-to-length roller shear located in the infeed area consists of a cutting head with hardened roller blades which can be reground or replaced as required with little effort. The cutting head is mounted on a maintenance-free linear roller guide and is driven by a toothed belt. This ensures a clean and burr-free cut. The shortest share length for this cutting method is approx. 700 mm. For shorter coulter lengths from approx. 100 mm, additional cutting devices are optionally available for mounting in the outfeed area of the QUADRO. Depending on the material and profile type, a QA60 (only for non-ferrous metals) can be used for the cut-off. For the production of conical profile webs, the QUADRO-KS is additionally equipped with an LS longitudinal cut-off device in the infeed area. This allows the conical longitudinal cut to be made before profiling.

In the subsequent profiling area, there is the proven interchangeable cassette system. Depending on the profile type, cassettes with 10 or 12 profiling stations can be accommodated there. The profile can be changed in a very short time by swiveling the cassettes or by changing the cassettes. When swiveling the cassettes, the changeover time takes only a few minutes and it can be implemented quickly and easily without auxiliary equipment.

Auxiliary equipment such as a forklift, table crane or overhead crane is required for cassette changeover. But here, too, the maximum changeover time is less than 20 minutes. The hardened and surface-treated profile rollers of the exchangeable cassettes are preset at the factory for material thicknesses between 0.5 – 0.7 mm (exception: special or facade profiles optionally 0.6 – 0.8 mm or 0.8 – 1.0 mm). For automatic processing of different lengths and quantities, the QUADRO-KS is equipped with a PLC. Input is made via a menu-guided touch panel. For the conical profiling operating mode, a separate submenu is called up on the touch screen. There, the necessary length entries for short width A, long width B and web length can be entered directly via a touch screen on the control. The control system then calculates a setting value for the inclined position of the cassette on the adjustment side. For this purpose, the cassette is adjusted by means of a handwheel via an adjustment spindle according to the specified value and then manually pushed to the start position. In the conical profiling mode, profiling can only be performed in a single cycle. This means that after the profile has left the machine, the movable cassette of the adjustment side must first be pushed back manually to the start position. Then the next web is conically cut and profiled.

When profiling from coil in the parallel profiling operating mode, the desired length and number of pieces are first entered on the touch panel. The manually fed strip material is drawn into the machine by means of the driven transport rollers. Once the programmed length has been reached, the drive, which is controlled by a frequency converter, stops and the cut-off cut is made automatically by means of driven roller shears. The overrun and thus the length tolerance is approx. 1 – 2 mm. In automatic mode, the restart of the next web is automatic. In single-cycle mode, the restart is triggered by the operator in each case. After the last profile web has been separated, further material feed can be stopped via a coupling lever and the belt can be retracted manually from the feed area.

- Technical Information

-

TECHNICAL INFORMATION

Supply voltage 230 V / 50 Hz / 1 Ph.

230 V / 60 Hz / 1 Ph.

400 V / 50 Hz / 3 Ph.

400 V / 60 Hz / 3 Ph.Drive power 2.2 kW Operating speed Default: 14 m/min

Optional: 20 m/minInfeed height 900 mm Infeed width 300 – 800 mm Shortest panel length 700 mm (depending on material and profile) Length tolerance approx. 1 – 2 mm Processable materials

(profile dependent)Non-ferrous metals: Either 0.6 – 0.8 mm or 0.8 – 1.0 mm (has to be set before ordering)

Non-ferrous metals: 1.0 – 1.2 mm (only with façade profiles)

Steel (320 N/mm²): 0.55 – 0.70 mm

Stainless steel: Max. 0.5 mmDimensions (L x W x H) 3,830 mm x 2,045 mm x 1,275 mm Weight approx. 1,770 kg (with exchangeable cassettes) - Control Variants

-

CONTROL VARIANTS

TOUCH PANEL CONTROL (PLC)

- Control panel with 5,7 Zoll touch screen (STN / colored)

- 4096 displayable colors

- Resolution 320 x 240

- Multilingual menu language

- User-friendly operator interface

- 25 program memory locations with each 40 program steps

- Manual operation as jogging mode

- Automatic operation in single-step and continuous operation

- Setting-up mode

- Feeder speed continuously adjustable with the control panel

TOUCH PANEL CONTROL (PLC) WITH GUIDE RAIL UNIT

- Control panel with 5,7 ” touch screen (STN / colored)

- 4096 displayable colors

- Resolution 320 x 240

- Multilingual menu language

- User-friendly operator interface

- 25 program memory locations with each 40 program steps

- Manual operation as jogging mode

- Automatic operation in single-step and continuous operation

- Setting-up mode

- Feeder speed continuously adjustable with the control panel

- Guide rail unit for comfortable operation of the control in the infeed or discharge area of the machine

TOUCH PANEL CONTROL (PLC) WITH GUIDE RAIL UNIT

- Control panel with 10,4 ” touch screen (STN / colored)

- 4096 displayable colors

- Resolution 640 x 480

- Multilingual menu language

- User-friendly operator interface

- 25 program memory locations with each 40 program steps

- Manual operation as jogging mode

- Automatic operation in single-step and continuous operation

- Setting-up mode

- Feeder speed continuously adjustable with the control panel

- Guide rail unit for comfortable operation of the control in the infeed or discharge area of the machine

- Profile Information

-

PROFILE INFORMATION

CHANGING CASSETTES WITH 10 ROLLER STATIONS BOTH SIDES AND MAY BE SWIVELED

You can select 2 profiles

PROFILE SELECTION

Double Standing Seam in height 25, 32 and 38 mm Double Standing Seam with Clip Relief in height 25, 32 and 38 mm Snap in height 25 and 38 mm Snap with Clip Relief in height 25 and 38 mm Nail Strip in height 25 and 38 mm U-profile max. 36 mm PROFILE INFORMATION

Profile Standing Seam

Profiles Snap and NailstripCHANGING CASSETTES WITH 10 ROLLER STATIONS ONE-SIDED AND CAN NOT BE SWIVELED

You can select 1 profile

PROFILE SELECTION

Double Standing Seam50 mm Double Standing Seam 50 mm with Clip Relief Double Standing Seam 50 mm (2″) USA Version PROFILE INFORMATION

Profile Standing Seam

CHANGING CASSETTES WITH 12 ROLLER STATIONS ONE-SIDED AND CAN NOT BE SWIVELED

you can select 1 profile

PROFILE SELECTION

Snap Lok 43,5 (1 3/4″) Sofit Panel Wall Panel Step Panel

Profile Information

Profiles Snap and Nailstrip

Profile facade profile Prof88 and SOFFIT

Profile facade profile stepped tile panelSPECIAL PROFILES ACCORDING TO CUSTOMER SPECIFICATIONS

Here some examples for special profiles:

PROFILE SELECTION

HohlumschlagFensterbank 1Fensterbank 2TraufblechLandhaus 1Landhaus 2FassadenpaneelKühlfahrzeugeindeckung 1Kühlfahrzeugeindeckung 2Kühlfahrzeugeindeckung 3LeistendachDachprofilContainereindeckung 1Containereindeckung 2Kassettenpaneel - More Information

-

MORE INFORMATION

As with the QUADRO profiling machine system, the QUADRO-KS variant can also produce sheet metal profiles from a wide range of applications in a user-friendly manner and within the shortest possible changeover time in the highest quality with just one basic machine. The well-known exchangeable cassette system with 10 or 12 forming stations is used to produce the various profile shapes.

Due to the clever design, the customer is able to determine the equipment and thus the application area of the machine individually himself. Of course, the machine can also be retrofitted at any time with additional cassettes or extensive accessories.

The QUADRO-KS is built on a robust base frame and is designed to be mobile with 4 castors. Two casters can be fixed to prevent unintentional rolling away. Furthermore, the crane lugs included in the scope of delivery and the forklift pockets attached to the frame enable the machine to be transported safely on the construction site. This ensures flexible use of the machine both in operation and on the construction site. Hinged covers, which are secured by a safety device, protect the machine and the operator and facilitate the adjustment work.

The infeed width can be continuously adjusted between 300 and 800 mm via a handwheel with the proven spindle system. For tapered operation, the spindle adjustment is disengaged so that the adjustment side can move freely laterally in a special linear guide, depending on the inclined position. In the infeed area, the QUADRO-KS is equipped with robust ball-bearing infeed guides on the right and left for stable guidance of the strip material. These are designed to be separately adjustable for adjusting the outer edges of the profile. This allows the strip to be fed smoothly and without play.

The additionally reinforced cut-to-length roller shear located in the infeed area consists of a cutting head with hardened roller blades which can be reground or replaced as required with little effort. The cutting head is mounted on a maintenance-free linear roller guide and is driven by a toothed belt. This ensures a clean and burr-free cut. The shortest share length for this cutting method is approx. 700 mm. For shorter coulter lengths from approx. 100 mm, additional cutting devices are optionally available for mounting in the outfeed area of the QUADRO. Depending on the material and profile type, a QA60 (only for non-ferrous metals) can be used for the cut-off. For the production of conical profile webs, the QUADRO-KS is additionally equipped with an LS longitudinal cut-off device in the infeed area. This allows the conical longitudinal cut to be made before profiling.

In the subsequent profiling area, there is the proven interchangeable cassette system. Depending on the profile type, cassettes with 10 or 12 profiling stations can be accommodated there. The profile can be changed in a very short time by swiveling the cassettes or by changing the cassettes. When swiveling the cassettes, the changeover time takes only a few minutes and it can be implemented quickly and easily without auxiliary equipment.

Auxiliary equipment such as a forklift, table crane or overhead crane is required for cassette changeover. But here, too, the maximum changeover time is less than 20 minutes. The hardened and surface-treated profile rollers of the exchangeable cassettes are preset at the factory for material thicknesses between 0.5 – 0.7 mm (exception: special or facade profiles optionally 0.6 – 0.8 mm or 0.8 – 1.0 mm). For automatic processing of different lengths and quantities, the QUADRO-KS is equipped with a PLC. Input is made via a menu-guided touch panel. For the conical profiling operating mode, a separate submenu is called up on the touch screen. There, the necessary length entries for short width A, long width B and web length can be entered directly via a touch screen on the control. The control system then calculates a setting value for the inclined position of the cassette on the adjustment side. For this purpose, the cassette is adjusted by means of a handwheel via an adjustment spindle according to the specified value and then manually pushed to the start position. In the conical profiling mode, profiling can only be performed in a single cycle. This means that after the profile has left the machine, the movable cassette of the adjustment side must first be pushed back manually to the start position. Then the next web is conically cut and profiled.

When profiling from coil in the parallel profiling operating mode, the desired length and number of pieces are first entered on the touch panel. The manually fed strip material is drawn into the machine by means of the driven transport rollers. Once the programmed length has been reached, the drive, which is controlled by a frequency converter, stops and the cut-off cut is made automatically by means of driven roller shears. The overrun and thus the length tolerance is approx. 1 – 2 mm. In automatic mode, the restart of the next web is automatic. In single-cycle mode, the restart is triggered by the operator in each case. After the last profile web has been separated, further material feed can be stopped via a coupling lever and the belt can be retracted manually from the feed area.

MORE PRODUCTS AND SOLUTIONS

Profiling machine QUADRO

Our profiling machine QUADRO – For a wide range of profile variants, with exchangeable cassettes and 10 (swiveling) or 12 forming stations. Processing of sheet material or from coil up to 800 mm, with PLC and motorized roller shear.

Profiling machine QUADRO-XL

Our profiling line QUADRO-XL – High-quality production of sheet metal profiles from the most different fields of application and with the shortest changeover time

Profiling machine QUADRO-XXL

Our profiling machine QUADRO-XXL – Built on a robust base frame and designed mobile with 4 casters