A profiling machine from the robust SPM/PMC series, featuring a motorized roller shear RSM for cross-cutting before profile shaping. It is designed to produce double standing seams with a height of 25 mm or 32 mm, available in either the standard shape (SPM-RSM) or with clip relief (PMC-RSM).

FEATURES

- Sturdy and versatile, ideal for a wide range of double standing seam profile applications

- Modular construction allows for retrofitting with additional components at any time

- User-friendly PLC with touch panel for easy operation

- Motorized roller shear RSM for cross-cutting before profile shaping

- Optional roller blade LS for longitudinal cuts before profile shaping

- Includes band infeed and clutch for precise infeed stopping

- Capable of producing tapered, conical, or fitting panels in two work cycles

- Maximum infeed width of 830 mm, infinitely adjustable

- Optional special model SPM-RSM 1000 / PMC-RSM 1000 with a maximum infeed width of 1,050 mm

- Minimum panel length of 500 mm (depending on material)

- Available for standard double standing seam (SPM-RSM) or with clip relief (PMC-RSM)

- Roll sets available for 25 mm and 32 mm double standing seams

- Adjustable infeed guides on ball bearings for smooth material guidance

- Profile rollers made from high-quality special steel, offering excellent corrosion and wear resistance

- Resilient mounts for upper profile rollers ensure impression-free and low-wear production of panels

TECHNICAL INFORMATION

PROFILE INFORMATION

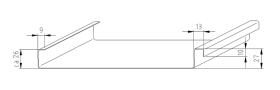

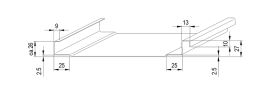

DIMENSIONS STANDING SEAM 25 AND 32 (SPM)

a) Axial Dimension

The corresponding strip widths result in the following profile dimensions for the profile height 25:

Optional version for 32 mm standing seam profile height:

b) Covering Width

During installation, the resulting covering widths must be considered:

Optional version for 32 mm standing seam profile height:

c) Variants

The following profiles can be manufactured on the SPM:

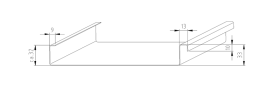

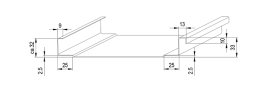

a) Axial Dimension

The corresponding strip widths result in the following profile dimensions for the profile height 25:

Optional version for 32 mm standing seam profile height:

b) Covering Width

During installation, the resulting covering widths must be considered:

Optional version for 32 mm standing seam profile height:

c) Variants

The following profiles can be manufactured on the PMC:

SYSTEM DESCRIPTION

Schlebach machines are characterized by the highest precision and user-friendliness. Get to know the folding techniques and backgrounds of the processing of metal.

ACCESSORIES

GUIDEBOY

Additional material guide for single-sided profile shaping of panels. The installation of the guideboy on any of the Schlebach profile shaping machine infeed guides requires little effort.

The Guideboy prevents the sheet material from shifting towards the centre of the machine during single-sided profile shaping operations. The required lateral force across the profiling direction may be adjusted by means of the directional angle, as well as an increase of the contact pressure on the sheet metal.

Damage to the material surface is ruled out by the use of high quality pressure rollers with a special rubber coating.

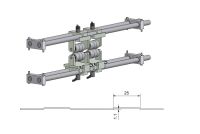

RIBBING ATTACHMENT 25MM

Ribbing attachment assembly to shape longitudinal ribs with a width of 25 mm and a depth of approximately 1.1 mm into the visible surface of profiled panels. The ribbing attachment assembly consists of a guide unit, upper and lower ribbing rollers with brackets.

The ribbing attachment assemblies are equipped with high-quality ribbing rollers on ball-bearings to ensure maximum protection of the surface from the panels being profiled. The ribbing attachments are continuously adjustable across the profile shaping direction to ensure that the distance of the ribs that are pressed into the panels may be designed as required.

Note: The profiling of ribs is not possible on conical shapes.

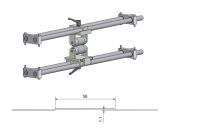

RIBBING ATTACHMENT 58MM

Ribbing attachment to shape longitudinal ribs with a width of 58 mm and a depth of approximately 1.1 mm into the visible surface of profiled panels. The ribbing attachment consists of a guide unit, upper and lower ribbing rollers with brackets. The ribbing attachments are equipped with high-quality ribbing rollers on ball-bearings to ensure maximum protection of the surface of the panels being profiled. The ribbing attachments are continuously adjustable across the profile shaping direction.

Note: The profiling of ribs is not possible on conical shapes.

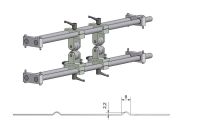

PENCIL RIBBING ATTACHMENT

Ribbing attachment to shape round ribs with a width of 8 mm and a depth of approximately 2.2 mm into the visible surface of profiled panels. The ribbing attachment consists of a guide unit, upper and lower ribbing rollers with brackets. The ribbing attachments are equipped with high-quality ribbing rollers on ball-bearings to ensure maximum protection of the surface of the panels being profiled. The ribbing attachment are continuously adjustable across the profile shaping direction. This ensures that the distance of the ribs that are pressed into the panels may be adjusted as required.

Note: The profiling of ribs is not possible on conical shapes.

CONCAVE CURVING ATTACHMENT

Concave curving attachment for the production of concave folded profile panels with a maximum height of 25 mm and a minimum bending radius of 3000 mm. The concave curving attachment can be attached to the exit area of the profile shaping machine and is suitable for retrofitting. The folded profiles produced by means of the profile shaping machine are automatically fed to the concave curving attachment and bent to the desired radius by adjustable pressure rollers. The concave curving attachment consists of two bending assemblies, one for the side lacking overlap as well as one for the overlapping side of the profile.

Note: Concave curving is only possible at parallel shapes profiled on both sides.

DECOILER AH1250A1

DECOILER AH1250K5

DECOILER AH-PFL

DECOILER TRANS-ASPO

- Technical Information

-

TECHNICAL INFORMATION

- Profile Information

-

PROFILE INFORMATION

DIMENSIONS STANDING SEAM 25 AND 32 (SPM)

a) Axial Dimension

The corresponding strip widths result in the following profile dimensions for the profile height 25:

Optional version for 32 mm standing seam profile height:

b) Covering Width

During installation, the resulting covering widths must be considered:

Optional version for 32 mm standing seam profile height:

c) Variants

The following profiles can be manufactured on the SPM:

DIMENSIONS STANDING SEAM 25 AND 32 CLIP RELIEF (PMC)a) Axial Dimension

The corresponding strip widths result in the following profile dimensions for the profile height 25:

Optional version for 32 mm standing seam profile height:

b) Covering Width

During installation, the resulting covering widths must be considered:

Optional version for 32 mm standing seam profile height:

c) Variants

The following profiles can be manufactured on the PMC:

SYSTEM DESCRIPTION

Schlebach machines are characterized by the highest precision and user-friendliness. Get to know the folding techniques and backgrounds of the processing of metal.

- Accessories

-

ACCESSORIES

GUIDEBOY

Additional material guide for single-sided profile shaping of panels. The installation of the guideboy on any of the Schlebach profile shaping machine infeed guides requires little effort.

The Guideboy prevents the sheet material from shifting towards the centre of the machine during single-sided profile shaping operations. The required lateral force across the profiling direction may be adjusted by means of the directional angle, as well as an increase of the contact pressure on the sheet metal.

Damage to the material surface is ruled out by the use of high quality pressure rollers with a special rubber coating.

RIBBING ATTACHMENT 25MM

Ribbing attachment assembly to shape longitudinal ribs with a width of 25 mm and a depth of approximately 1.1 mm into the visible surface of profiled panels. The ribbing attachment assembly consists of a guide unit, upper and lower ribbing rollers with brackets.

The ribbing attachment assemblies are equipped with high-quality ribbing rollers on ball-bearings to ensure maximum protection of the surface from the panels being profiled. The ribbing attachments are continuously adjustable across the profile shaping direction to ensure that the distance of the ribs that are pressed into the panels may be designed as required.

Note: The profiling of ribs is not possible on conical shapes.

RIBBING ATTACHMENT 58MM

Ribbing attachment to shape longitudinal ribs with a width of 58 mm and a depth of approximately 1.1 mm into the visible surface of profiled panels. The ribbing attachment consists of a guide unit, upper and lower ribbing rollers with brackets. The ribbing attachments are equipped with high-quality ribbing rollers on ball-bearings to ensure maximum protection of the surface of the panels being profiled. The ribbing attachments are continuously adjustable across the profile shaping direction.

Note: The profiling of ribs is not possible on conical shapes.

PENCIL RIBBING ATTACHMENT

Ribbing attachment to shape round ribs with a width of 8 mm and a depth of approximately 2.2 mm into the visible surface of profiled panels. The ribbing attachment consists of a guide unit, upper and lower ribbing rollers with brackets. The ribbing attachments are equipped with high-quality ribbing rollers on ball-bearings to ensure maximum protection of the surface of the panels being profiled. The ribbing attachment are continuously adjustable across the profile shaping direction. This ensures that the distance of the ribs that are pressed into the panels may be adjusted as required.

Note: The profiling of ribs is not possible on conical shapes.

CONCAVE CURVING ATTACHMENT

Concave curving attachment for the production of concave folded profile panels with a maximum height of 25 mm and a minimum bending radius of 3000 mm. The concave curving attachment can be attached to the exit area of the profile shaping machine and is suitable for retrofitting. The folded profiles produced by means of the profile shaping machine are automatically fed to the concave curving attachment and bent to the desired radius by adjustable pressure rollers. The concave curving attachment consists of two bending assemblies, one for the side lacking overlap as well as one for the overlapping side of the profile.

Note: Concave curving is only possible at parallel shapes profiled on both sides.

DECOILER AH1250A1

A decoiler for metal coils with a max. weight of 1,000 kg and a max. coil width of 1,250 mm. The decoiler consists of a welded frame and a continuously adjustable mandrel on ball bearings with centre adjustment. The clamping range of the mandrel ranges from a min. of 280 mm to a max. of 530 mm inner coil diameter (optionally up to 650 mm). The manual braking assembly prevents metal coil overtravel. The decoiler is mobile because the decoiler is equipped with four swivelling castors. Extendable supports may be used to clamp the decoiler on site.

DECOILER AH1250K5

A decoiler for metal coils with a max. weight of 5,000 kg and a max. coil width of 1,250 mm. The decoiler consists of an exceptionally stable welded frame and a continuously adjustable mandrel on ball bearings with centre adjustment. The clamping range extends from a min. of 380 mm to a max. of 530 mm inner coil diameter. A standard braking assembly prevents metal coil overtravel.

DECOILER AH-PFL

A decoiler with pneumatic clamping for metal coils with a max. weight of 2,000 kg and a max. coil width of 800 mm. The decoiler consists of a solid, welded base frame, and a pneumatically actuated floating mandrel (6 bar working pressure). Because of the one-sided, floating support, the decoiler may be loaded from the front by a forklift or crane. The clamping range extends from a min. of 380 mm to a max. of 420 mm inner coil diameter. The support plates that are supplied with the unit extend the clamping range of the mandrel from a min. of 480 mm to a max. of 520 mm. The max. permissible outer diameter of the coil is 1,100 mm. A pneumatic brake prevents any overrun of the metal coils. Four pneumatic cylinders can extend the castors when the decoiler must be moved manually. When the castors are retracted, the decoiler is placed on four stands, i.e. it is secured on site against it rolling away.

DECOILER TRANS-ASPO

The TRANS-ASPO uncoiler is for fast and simple holding of 1t coils. Due to the flying bearing and the manual height adjustment, the coil can be placed on the tensioning mandrel and tensioned manually without additional lifting equipment. The uncoiler is equipped with four travel rollers (two of which with fixing brake), and can therefore be placed easily in front of the working machine.

MORE PRODUCTS AND SOLUTIONS

Profiling machine SPM / PMC

Our profiling machine SPM / PMC – For the production of double standing seam profile in 25 mm or 32 mm height

Profiling machine SPM-RS / PMC-RS

Our profiling machine SPM-RS / PMC-RS – With roller shear RS for cross cutting by hand before profiling

Profiling machine SPM-LM-QA60 / PMC-LM-QA60

Our profiling machine SPM-LM-QA60 / PMC-LM-QA60 – With cut-to-length line QA60 for cross-cutting by hand with circular saw after profiling

Profiling machine SPA / PAC

Our profiling machine SPA / PAC – For continuous operation with hydraulic cut-off device for right-angled, burr- and twist-free cross-cutting

Profiling machine SPM-KS / PMC-KS

Our profiling machine SPM-KS / PMC-KS – For tapered sections to be profiled directly from the coil with double standing seam profile in 25 mm or 32 mm height

Profiling machine TWIN

Our profiling machine TWIN – A machine variant from the SPM series with cassettes loaded on both sides

Profiling machine HPM

Our profiling machine HPM – For the production of hollow wraps on flashings, for water rebate, verge, etc. from cut sheet metal.