EASY AND PERFECT BENDING OF COMPLEX FORMS

YOUR MULTI-TALENTED MACHINE. THE UK.

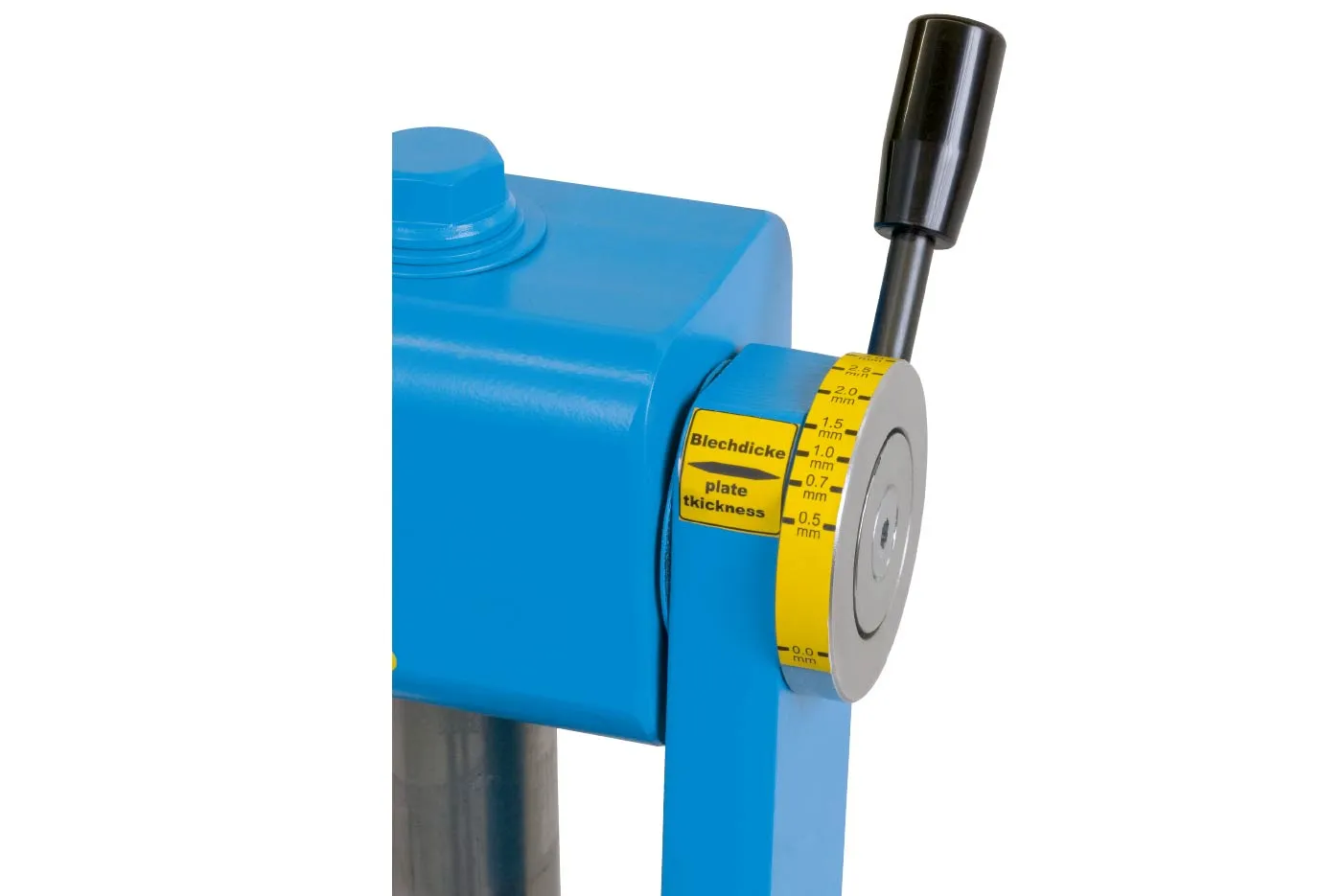

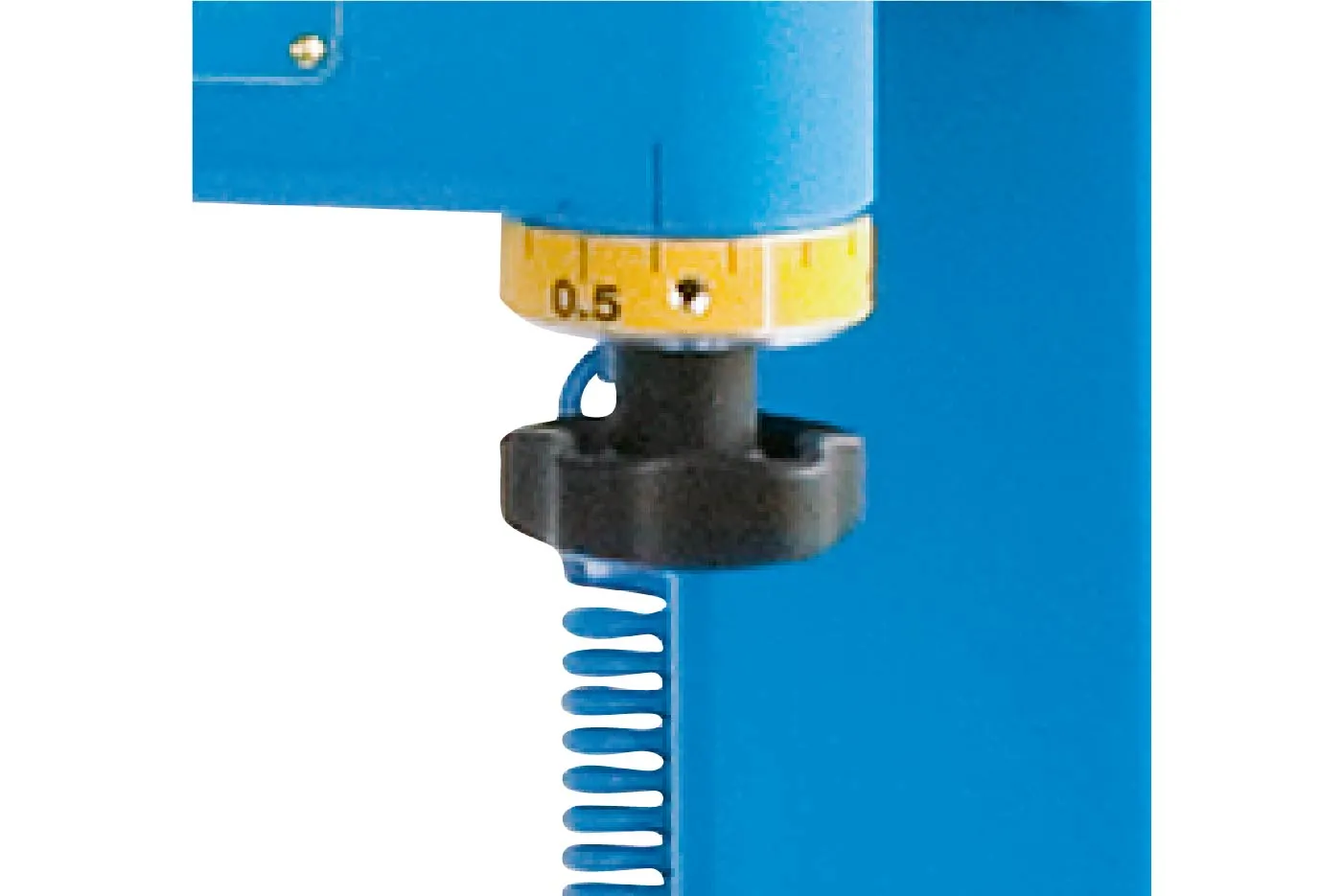

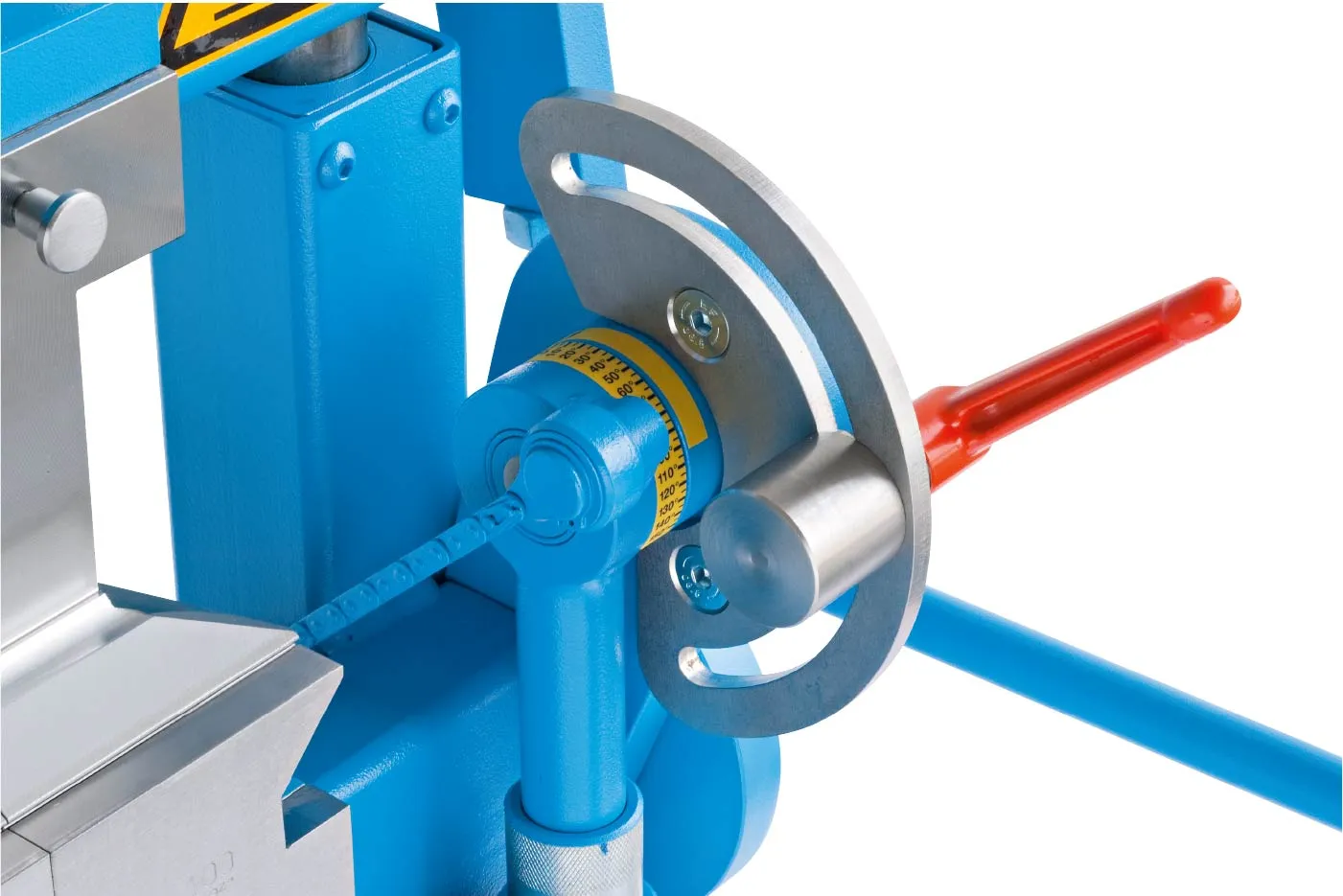

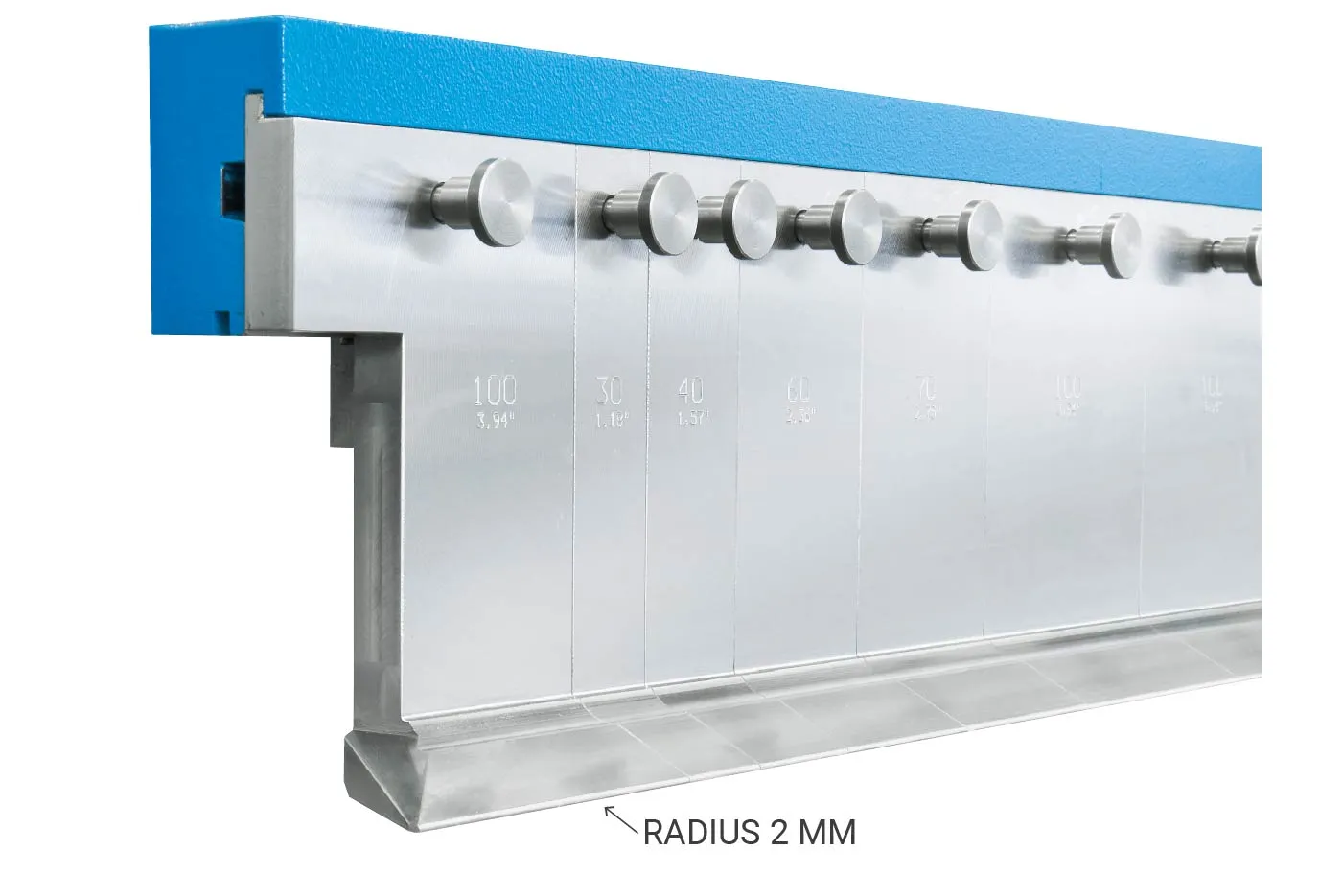

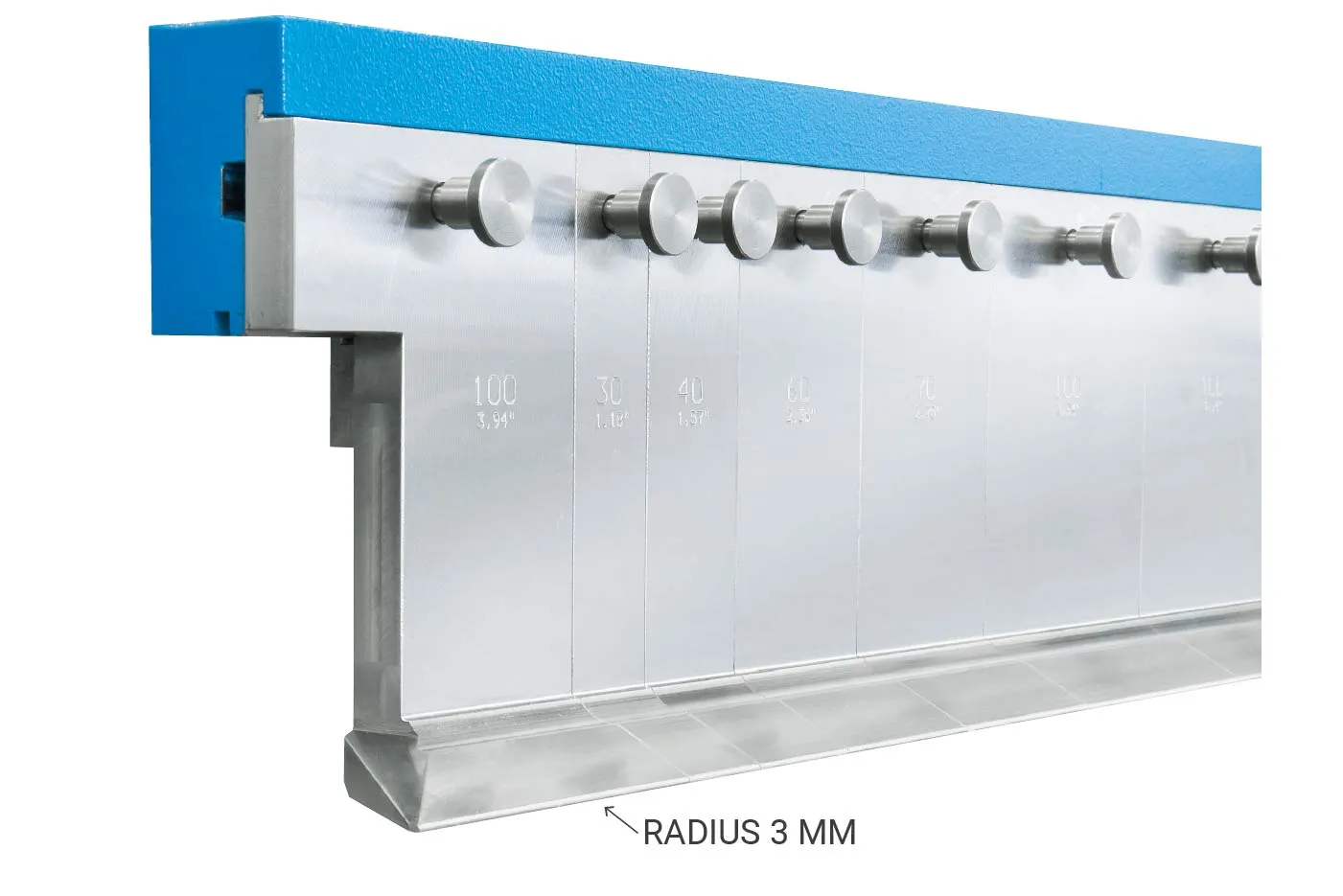

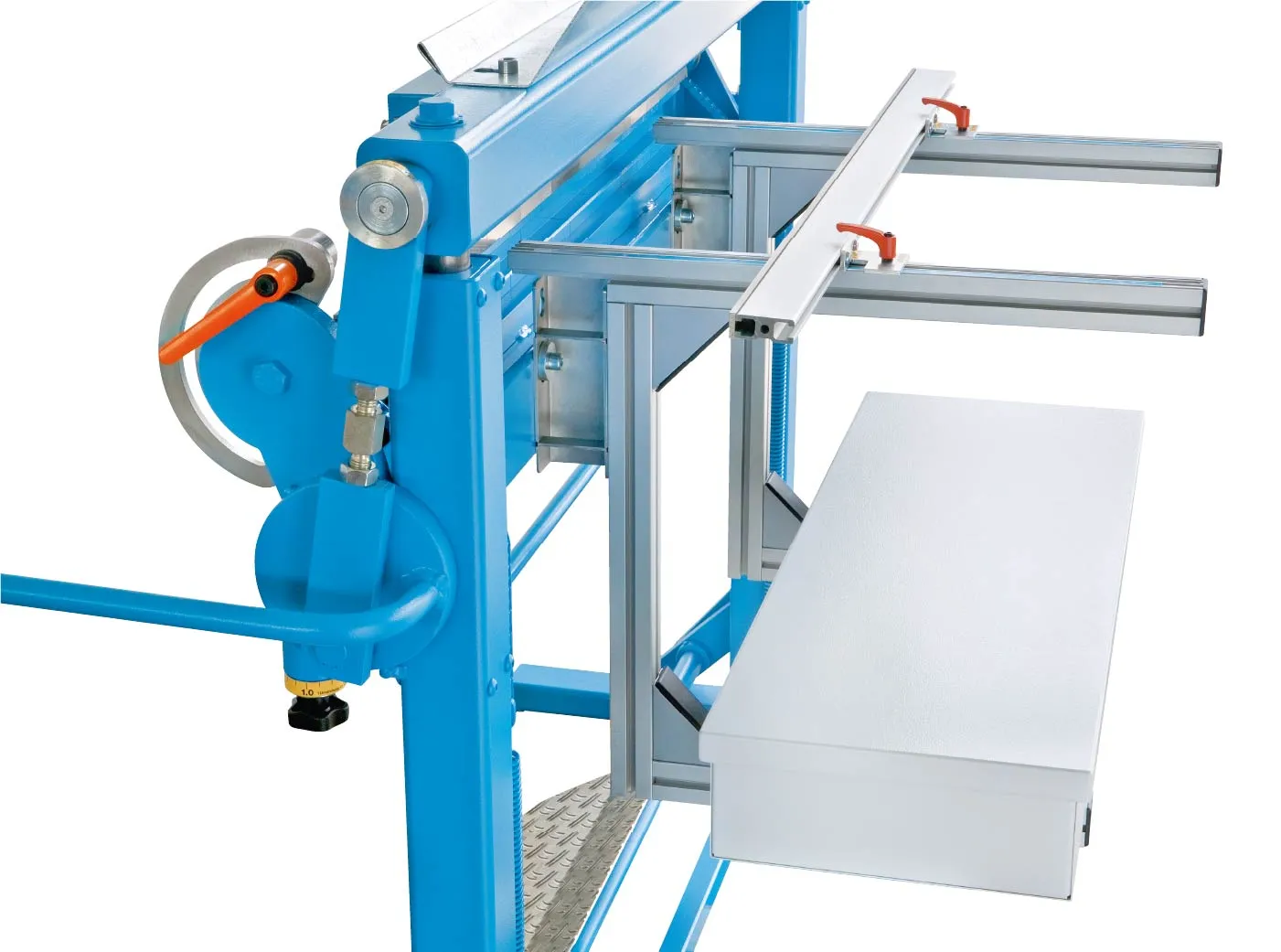

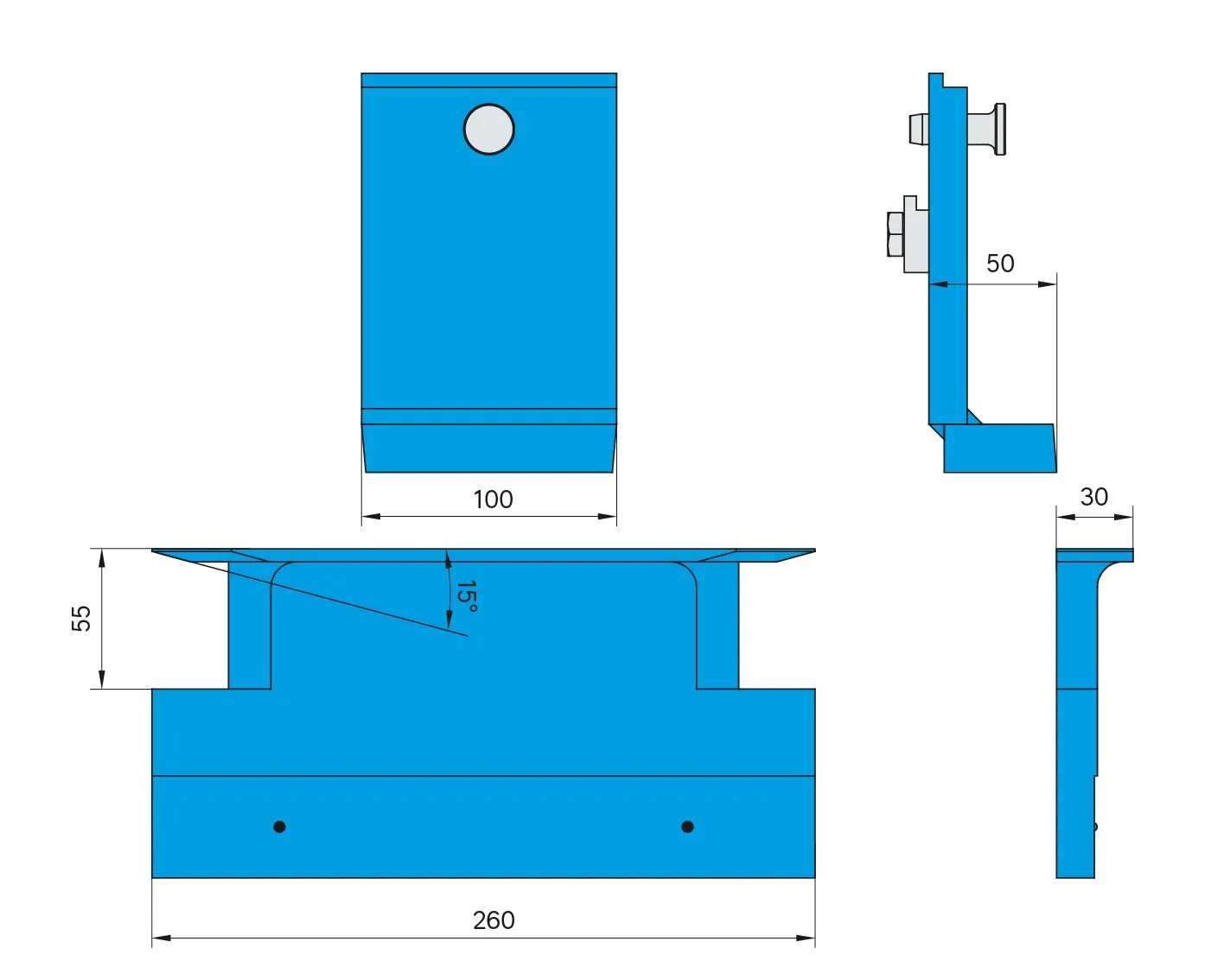

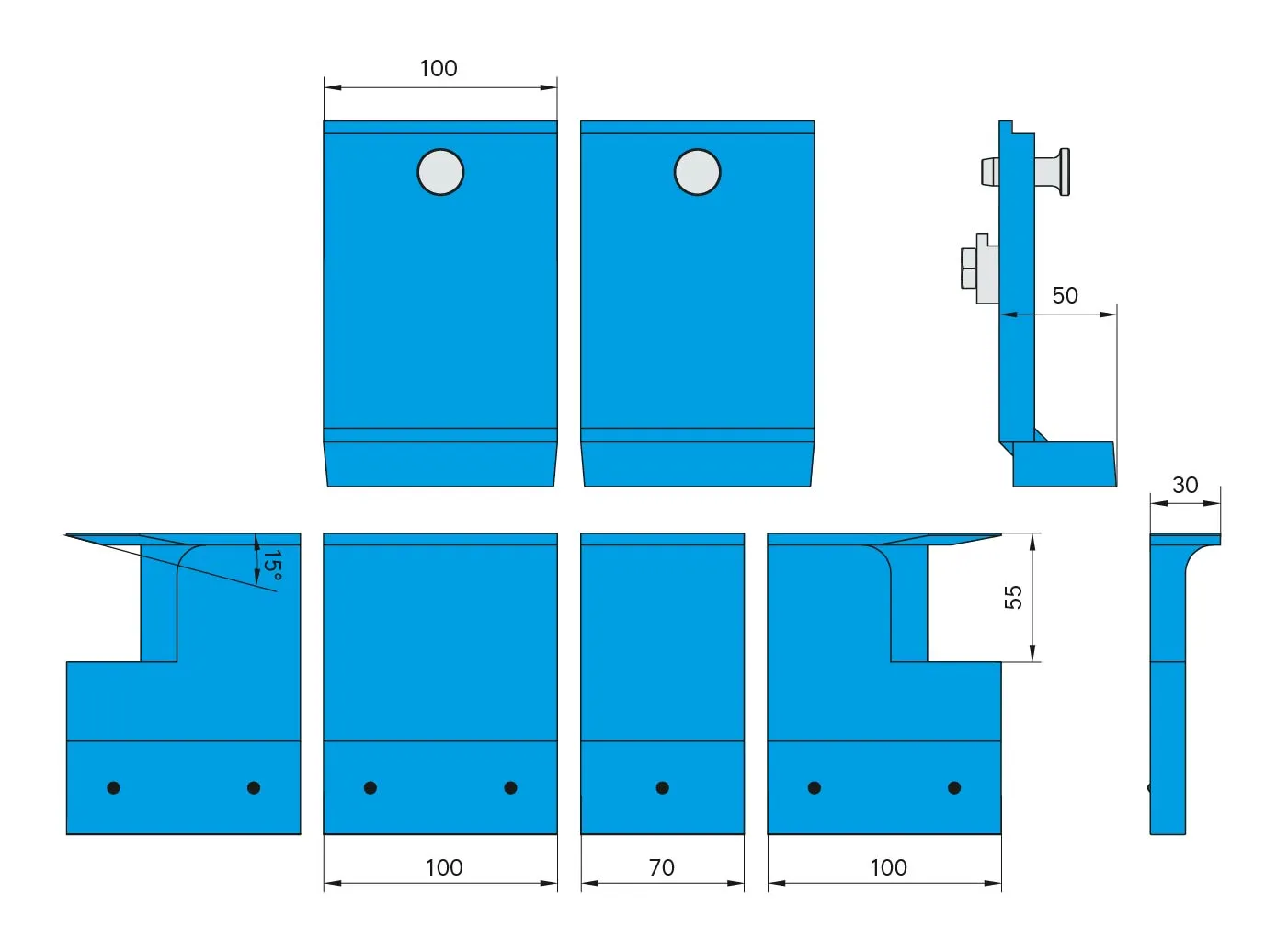

The Schechtl UK handles the production of special shapes, box and cassette forms and adjustment tasks. It can bend up to 1.50 mm steel and is available in working lengths 1 m and 1.25 m. The comprehensive range of standard equipment and many extension options make the UK a real multi-tool.