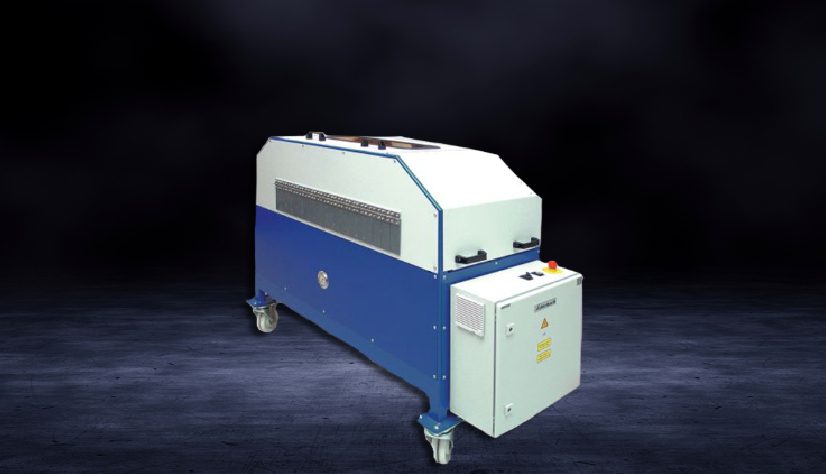

Electrohydraulic notching unit KLS for mechanical assembly preparation of pre-profiled panels with double standing seam 25, 32 and 38 mm with and without clip relief for roofs, dormers, façades and parapets.

FEATURES

- Notching of a round cutout in optionally 25, 32 and 38 mm profile height

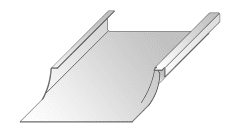

- Both standard and clip relief

- Notching and feeding-forward of parallel, tapered and trapezodial profile panels

- Eaves and roof inflexion points, channels, monopitch roofs, façade bases, faceplates, verge flashing and window lintels

- Profiled sheets are cut out and fed forward

- Burr-free cuts prevent tearing

- Double punching tools facilitate notchings for laying both from right to left, as well as from left to right

- Panels can therefore be prepared for the eaves, for building inflexion points or the upper parts

VIDEO

TECHNICAL INFORMATION

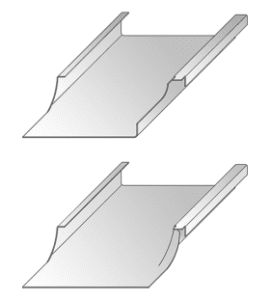

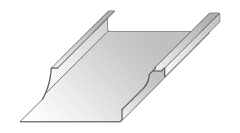

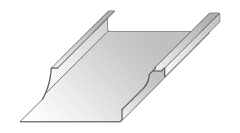

PROFILE INFORMATION

FUNCTIONS

1. NOTCHING

On the shown profile the profiling area can be notched on each side right or left. The notching depth is infinitely variable from 30 – 80 mm.

2. FEEDING FORWARD

The shown and notched profile can be produced on the female side with a expanding tool.

- Technical Information

-

TECHNICAL INFORMATION

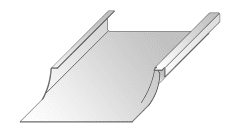

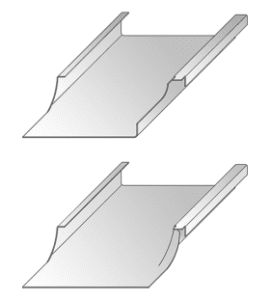

- Profile Infromation

-

PROFILE INFORMATION

- Technical Data

-

FUNCTIONS

1. NOTCHING

On the shown profile the profiling area can be notched on each side right or left. The notching depth is infinitely variable from 30 – 80 mm.

2. FEEDING FORWARD

The shown and notched profile can be produced on the female side with a expanding tool.

MORE PRODUCTS AND SOLUTIONS

Notching unit KLS 90

Our notching unit KLS 90 – For mechanical assembly preparation of pre-profiled panels

Notching unit EHA

Our EHA notching unit – For automated notching, driving and folding of pre-profiled panels with double lock standing seam 25, 32 and 38 mm

Bending unit UKST

Our UKST bending station – for flange mounting on profiling machines of the QUADRO series