Bending machines

EHRT bending machines of the Standard- and Professional Line are extremely powerful CNC bending machines. Their ideal use are small and medium series.

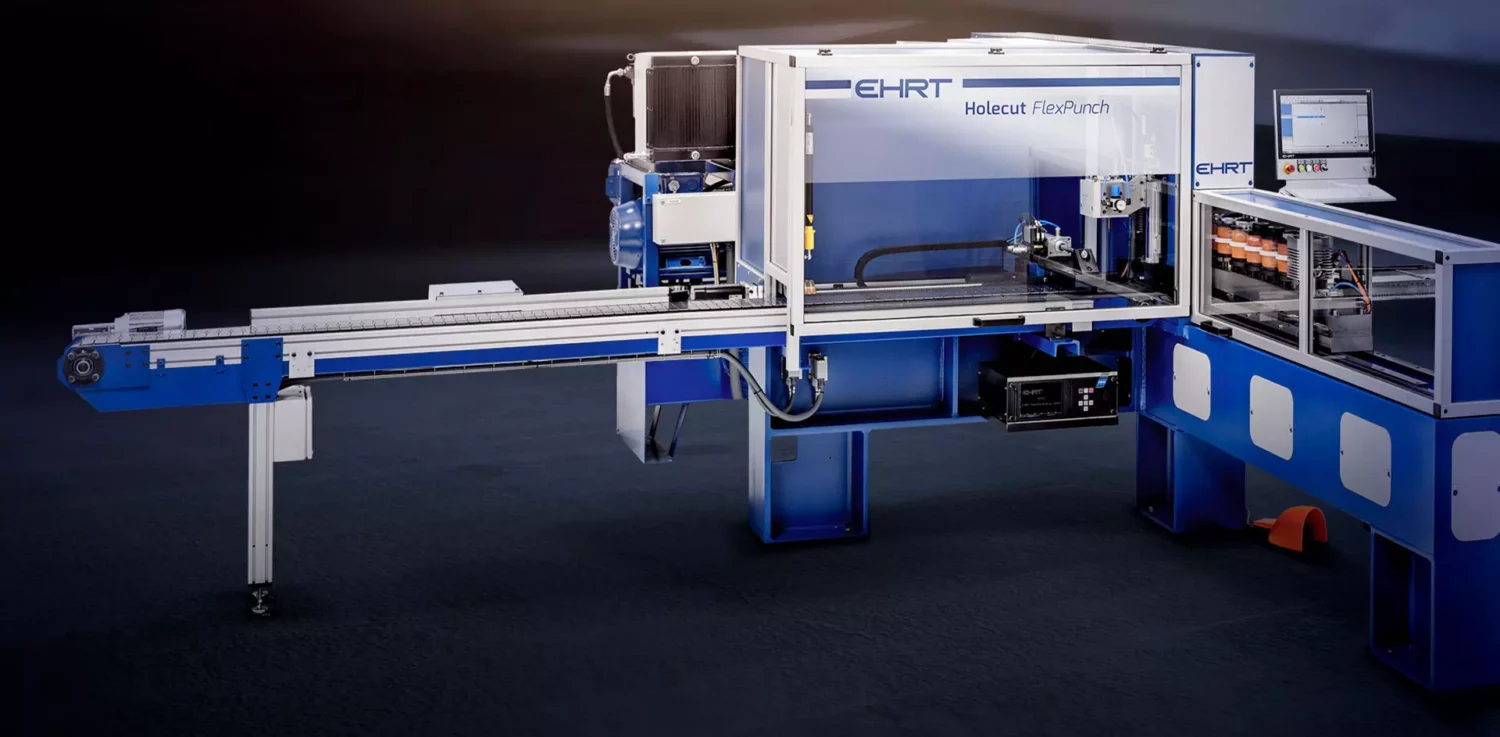

Punching machines

EHRT punching machines of the FlexPunch serie and Professional Line are extremely powerful CNC punching machines.

Software

The EHRT Software was developed for the intuitive operation with the bending- and punching machines.

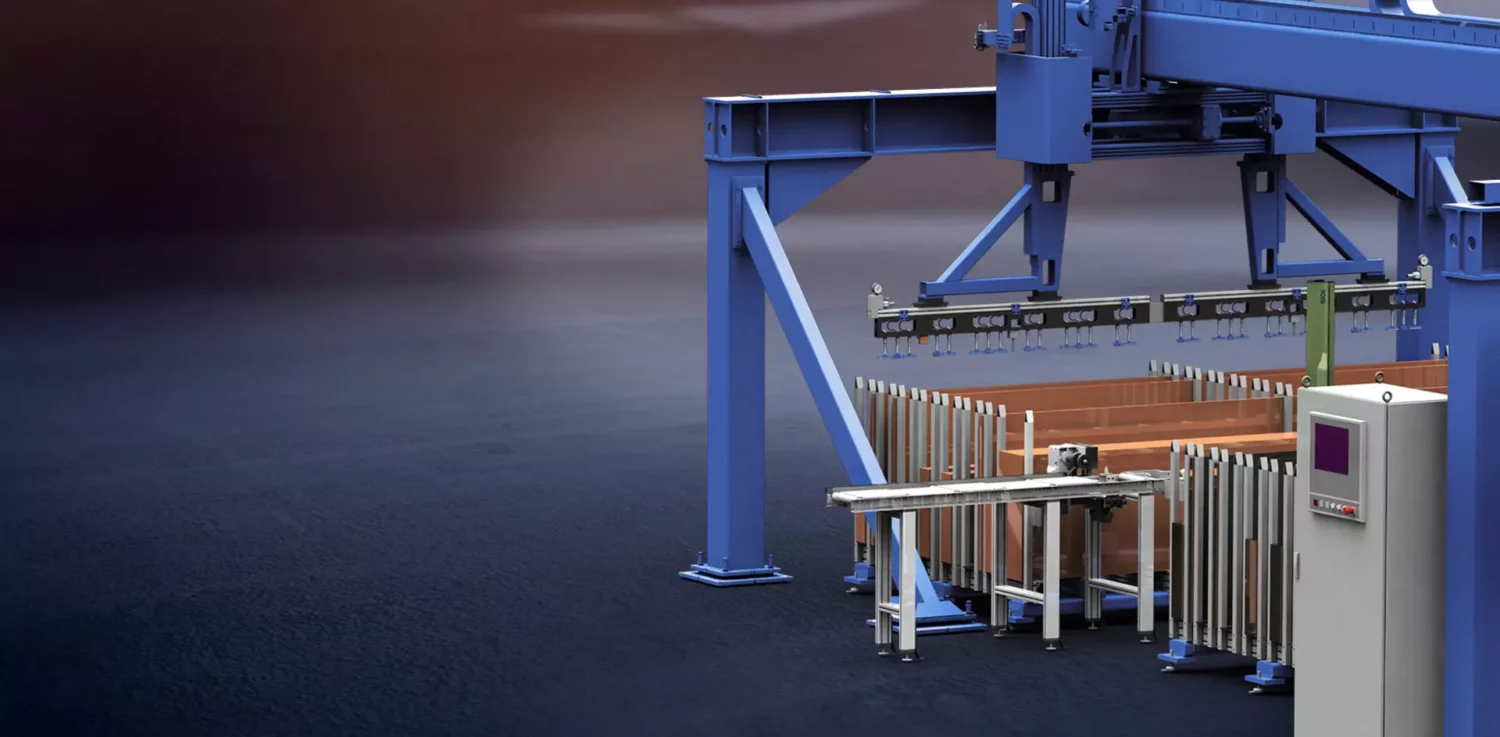

Material feeding systems

The material feeding systems enable half-automatic/ automatic feeding of busbars to the EHRT punching machines.

AUTOMATION

CY Laser Automation makes your Fiber Laser Cutting System efficient and productive.

CY2D

Find out all CY-Laser fiber laser cutting Systems

CYTUBE

Find more about Tube Laser Cutting System features

PROCESS OPTIONAL

Vega and Vortex: highest quality metal cut

USED

CYLASER systems used, overhauled and guaranteed